Relyon plasma developed the MediPlas® system based on DBD technology. The two coponents MediPlas® Drive and MediPlas® Reactor can be used in many fields of application such as industry or medical technology.

Dielectric Barrier Discharge Technology

The big advantage of the DBD technology (dielectric barrier discharge technology) is the easy establishment of non-equilibrium plasma conditions. With the DBD technology it can be established in a much simpler way than with other technologies. Microdischarges distributed over a surface with a lifespan of only a few nanoseconds pump hot electrons into the gas phase while the total process remains “cold” (far from thermodynamical equilibrium). Therefore, new species can be generated with high efficiency. High yield ozone generation is the most important process for many applications in water and air treatment.

Plasma components based on DBD technology

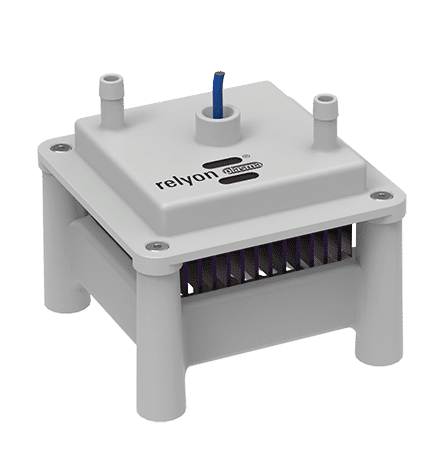

Relyon plasma developed two components based on DBD technology. The Mediplas® Reactor is a high-yield atmospheric DBD ozone generator with active cooling and humidity tolerance. Appliances with the MediPlas® Reactor can reduce the concentration of pathogens in contact with contaminated surfaces such as medical equipment, masks and tubing.

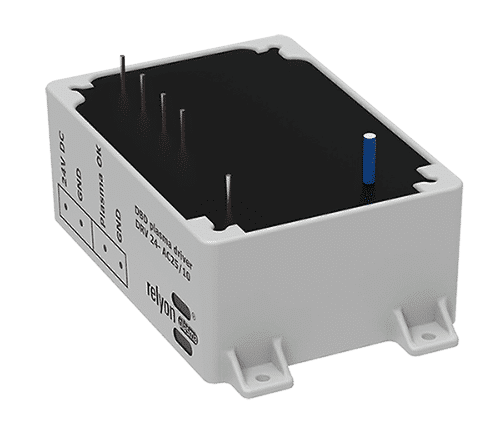

The MediPlas® Drive can drive customer specific DBD-assemblies with up to 300 pF capacity and an atmospheric air gap up to 2 mm distance from the ground electrode. Each MediPlas® Drive can feed three MediPlas® Reactor blocks.

Application of DBD technology

The are many fields of application for the DBD technology. It can be used in industry, medical technology, for treating water and air quality and much more. The tecnology is suitable for integration into everyday objects such as cupboards, vacuum cleaners, ventilation systems or waste bins. Because of the space-saving units the field of application is very broad. DBD technology offers unprecedented configuration options for operation in various media such as gas or at a liquid or solid interface within a wide range of pressure, energy-density and temperature.

Typical DBD configurations can be designed in planar or cylindrical geometries and can be operated under forced flow, jet-like or under diffusion or convection conditions. The basic principle an be scaled over a very wide range. The voltage amplitude, frequency and power of the AC source can easily be adapted to the needs of the application.