Ion Beam Etching (IBE) and Reactive Ion Beam Etching (RIBE).

Ion beam technology that allows films to be etched by the use of beams of charged ions in a high vacuum system.

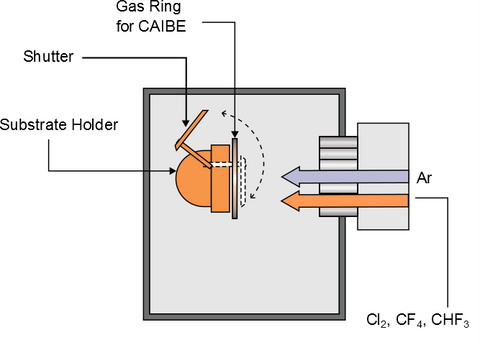

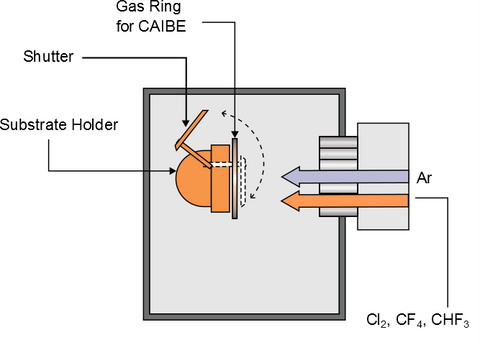

The ion beam is directed at the substrate to be patterned. Tilted features can be created with the unique ability to tilt the sample altering the direction of impact of the ion beam. Ion beam etching can be used in two ways:

- IBE uses charged non reactive ions

- RIBE uses reactive species to alter the film properties.

Highlights

- Allows beam energy and ion flux to be independently controlled

- Process takes place in a low pressure working environment

- Produces anisotropic etching

- Provides means for all known materials to be etched

- Allows angled profile control thanks to a variable etch beam angle relative to sample surface features

- RIBE enables fast etch rates and high selectivity etching of different materials through reactive species eg. Indium Phosphide (InP)

Features & Benefits

- Flexible configuration for advanced research applications

- Unmatched uniformity and process reproducibility for production

- Flexible wafer handling capability – open load, single wafer load lock or cassette-to-cassette robotic handler

- Accurate end point detection – SIMS, optical emission

- Two substrate holder options:

- 0 – 20 RPM, 0 – 300°C water cooled

- 0 – 500 RPM, quartz lamp heating with white light optical monitor (WLOM) option

- 15cm or 30cm RF Inductively Coupled Plasma (ICP) ion source

- Three grid assembly designs

- Grid designs tailored for specific etch requirements

- Filamentless DC plasma bridge neutraliser (PBN) for low maintenance