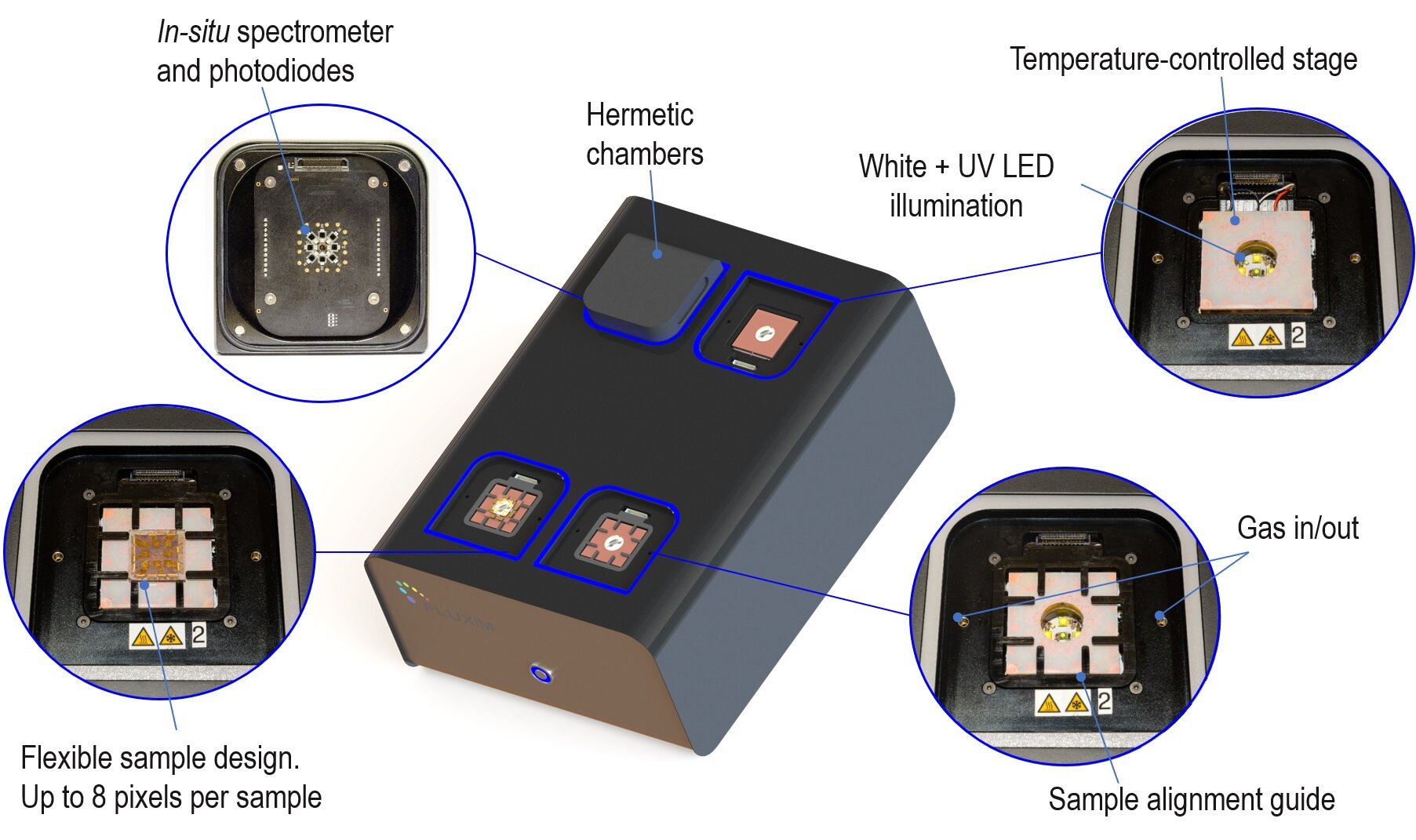

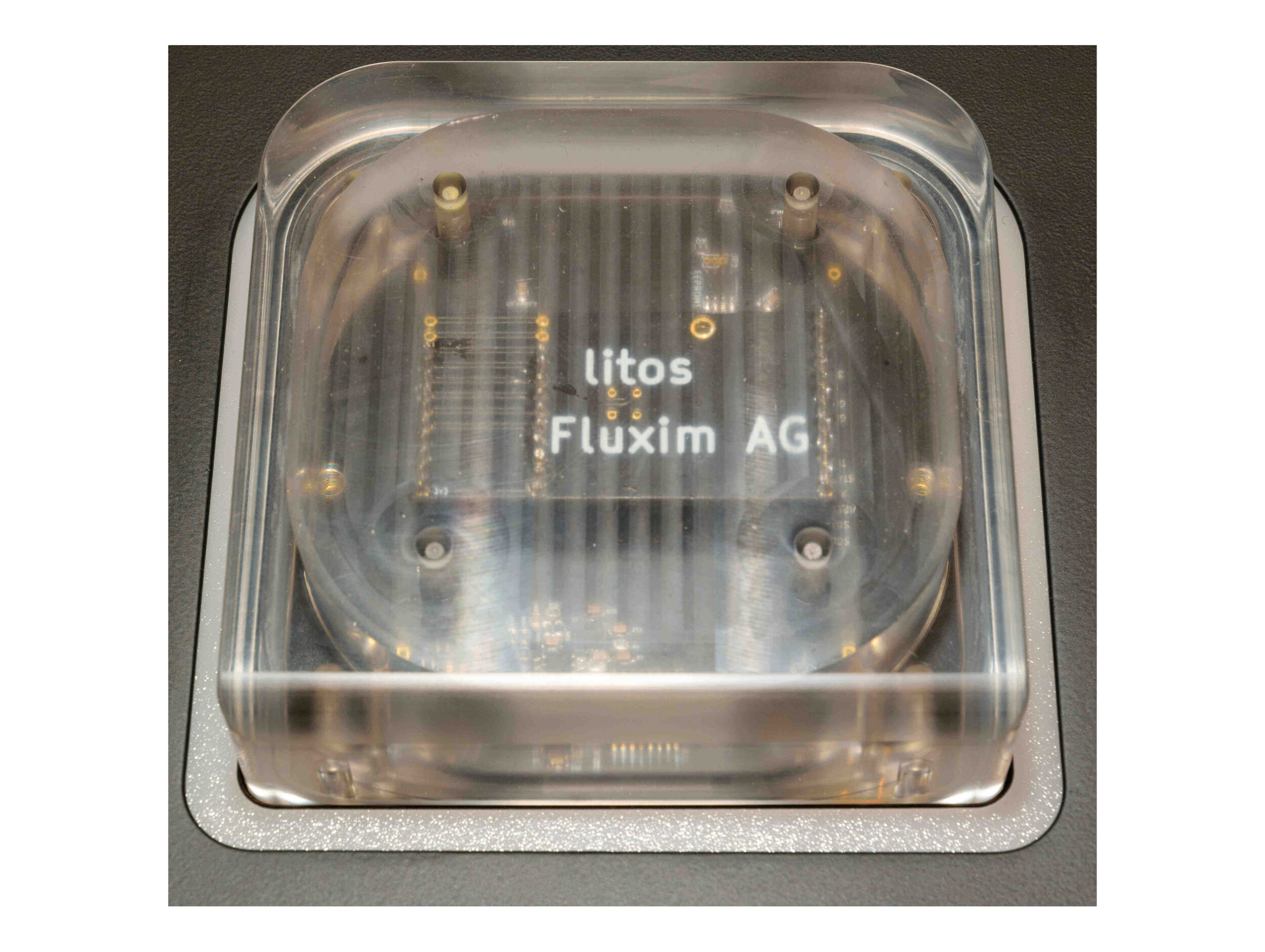

litos

Stress-Test Platform for Degradation Analysis of LEDs and Solar Cells

Advantages - Specifications - Sample Holder - Litos/Paios Integration - Atmospheric Module - Download Brochure

Overview

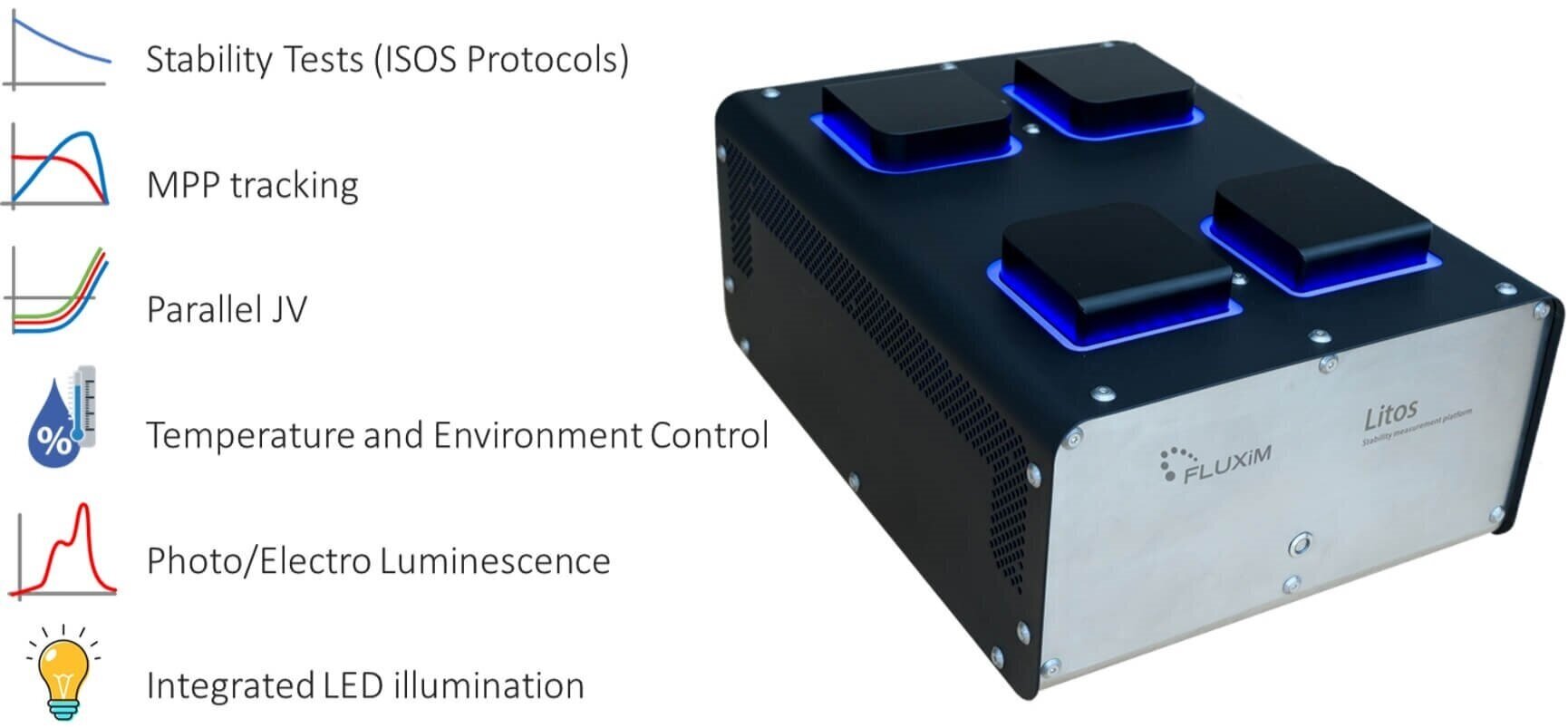

Litos is an advanced solar cell and LED stability lifetime measurement system. It has 8, 16, or 32 parallel stressing channels distributed over 4 sealed chambers. Each chamber has an individual temperature and illumination control. The wide range of stress conditions and the possibility of interfacing Litos with Paios for in-depth degradation analysis, make it a primary choice for researchers that want to understand the degradation behavior of organic, perovskite, and quantum-dots based solar cells and LEDs.

Advantages

-

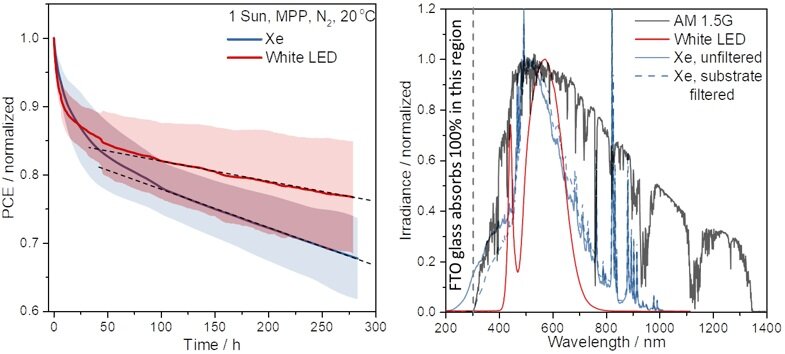

Stress tests on perovskite solar cells and organic solar cells, according to ISOS protocols.

-

8, 16, or 32 individual channels to address multiple solar cells or LEDs in parallel.

-

4 chambers with individual humidity sensors and independent illumination.

-

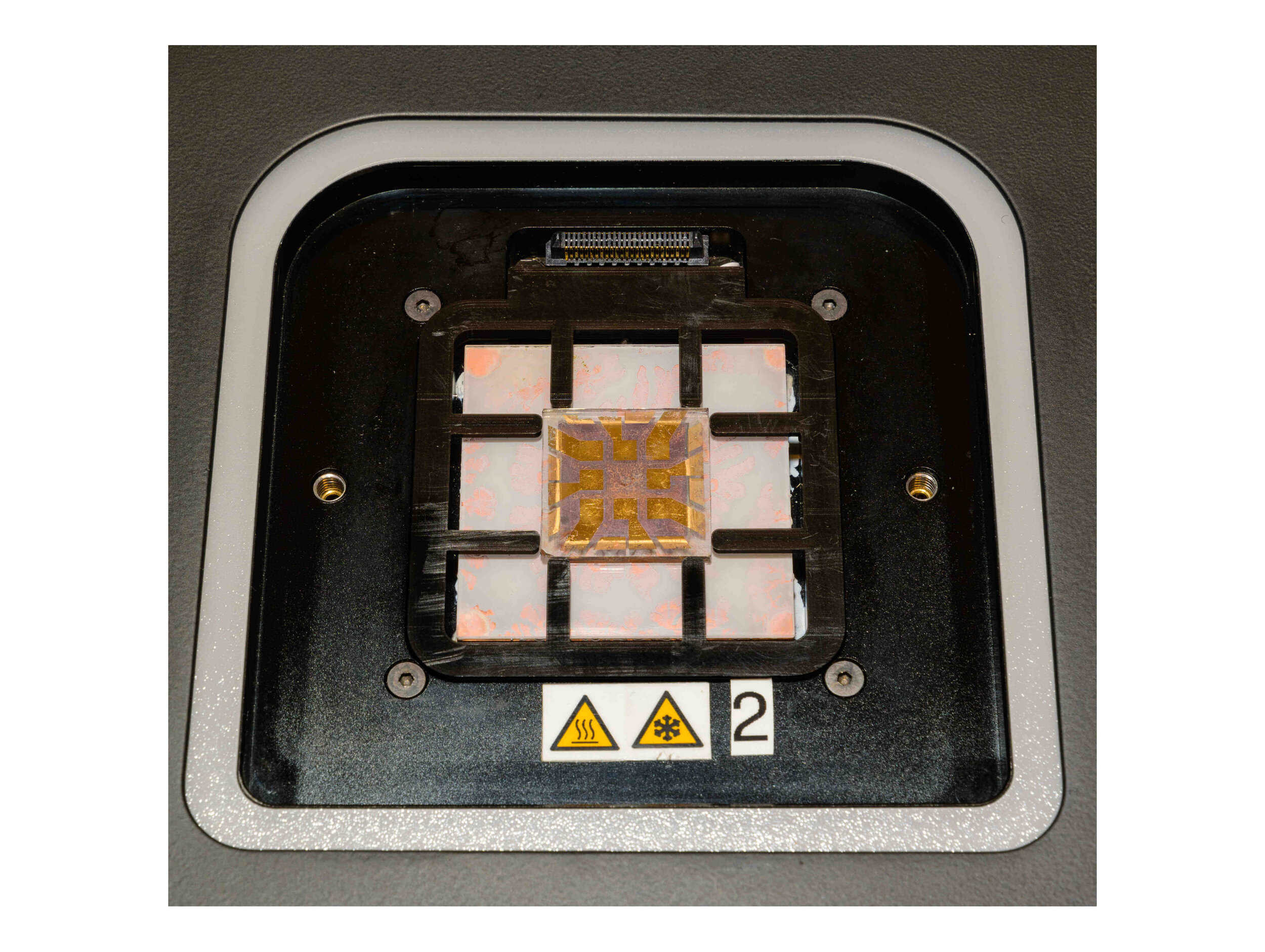

Design customized to the specific sample layout of the customer.

-

The Litos-Paios Integration provides a unique tool to understand the degradation mechanisms in solar cells and LEDs.

-

Patented OLED accelerated aging and lifetime estimation procedure.

-

Compatible with atmosphere-controlling equipment.

-

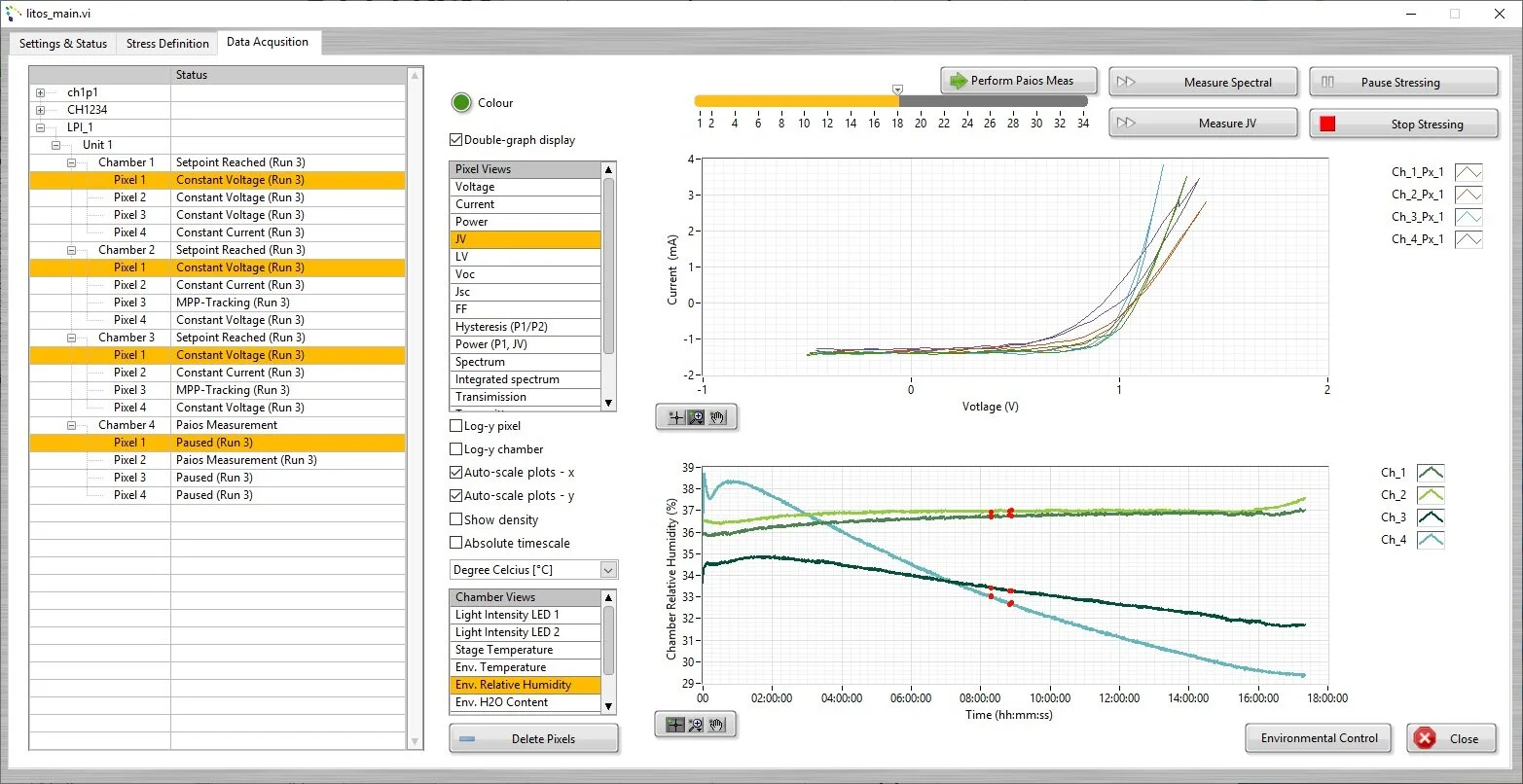

User-friendly software for automatic measurement control and parameter extraction.

Specifications

| Independent stressing and characterization of 32 device in 4 airtight chambers | |

|---|---|

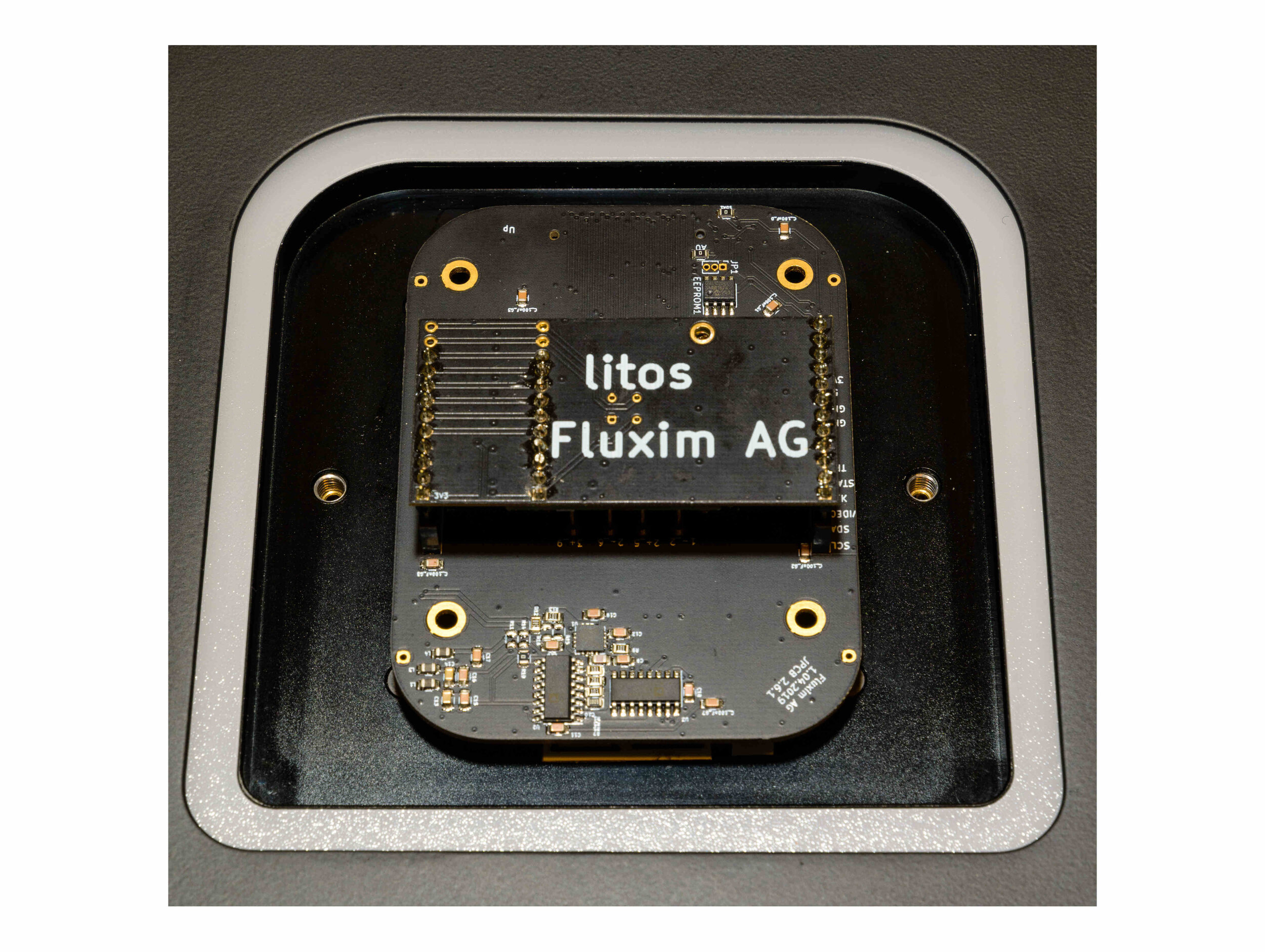

| Functionality | MPP, Voc, Jsc, JV(L), in-situ spectral measurements (PL and EL) |

| Operations | All channels are independent. Temperature/atmosphere controllers on each chamber. |

| Min/Max Voltages | -9 V to 9 V |

| Maximum current | 60 mA /channel |

| Temperature Range | 0 - 85°C |

| Sample Size | Up to 2 inches. The illumination area is around 3 cm^2. |

| Light Intensity | Up to 2 sun equivalent |

| Computer Connection | USB |

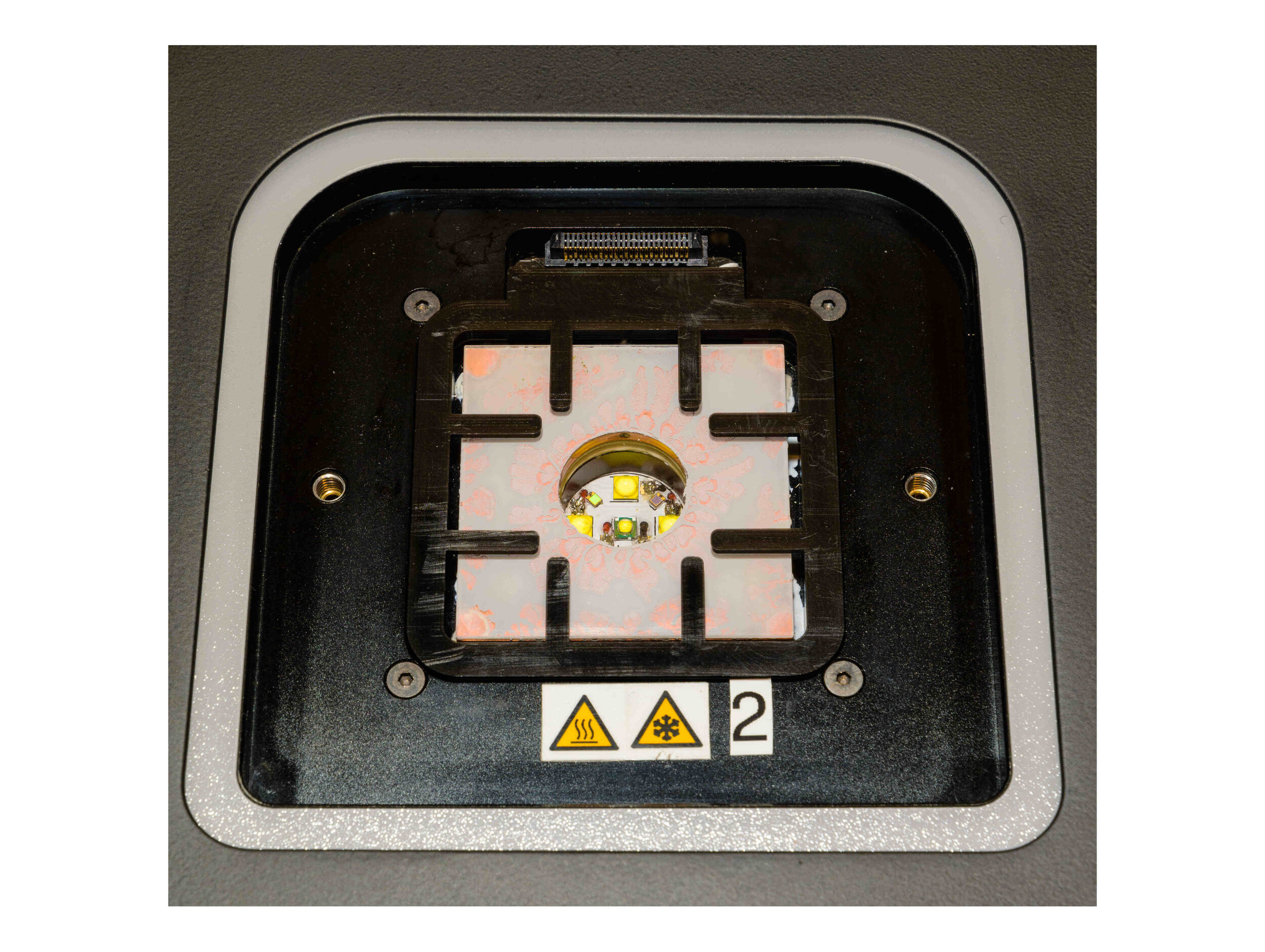

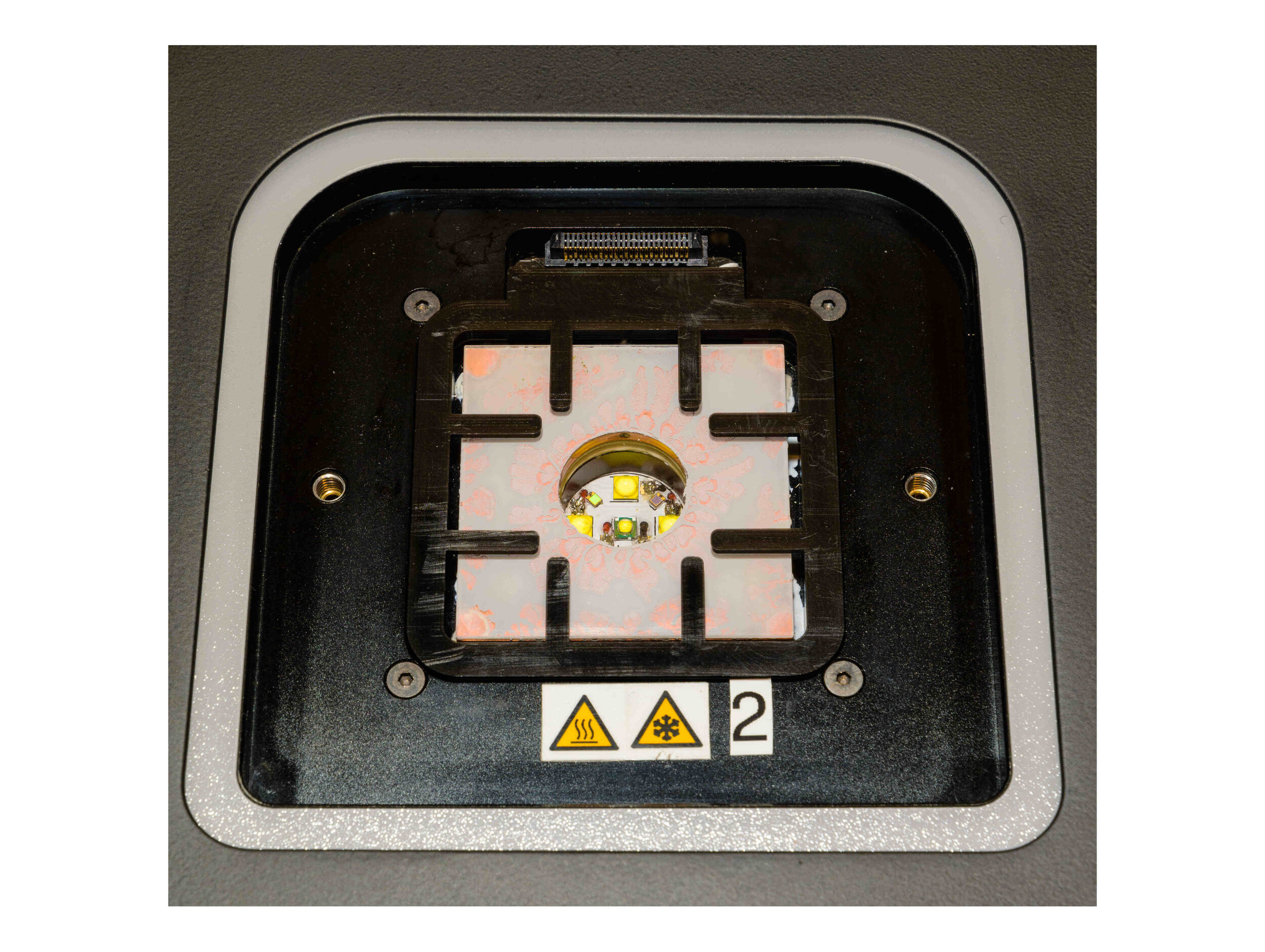

| Illumination | Integrated in each chamber. White + UV LEDs |

| Atmosphere Control | Sealed Chambers. Fluxim Atmosphere Control Module. |

Solar Cells

-

4 chambers with humidity and temperature sensors.

-

8, 16, or 32 individual channels. Samples up to 2 inches.

-

Maximum power point (MPP) tracking, constant voltage/current.

-

Temperature control of the individual sample 0 – 85 °C.

-

White and UV LED illumination (configurable). Independent illumination system for each chamber.

-

2 sun equivalent illumination.

-

In-situ UV-vis absorption is possible for bleaching detection.

LEDs

-

Constant current, constant luminance, constant voltage.

-

8, 16, or 32 individual channels. Samples up to 2 inches.

-

Compatible with Bottom and Top Emitting LEDs

-

Individual photodiode for each LED under test.

-

Patented LED accelerated aging and lifetime estimation procedure.

-

1 dedicated spectrometer in each chamber.

-

Temperature control of the individual sample 0 – 85 °C.

Fluxim Characterization Suite software is compatible with Paios for in-depth degradation analysis.

A combined version for both Solar Cells and LEDs is also available.

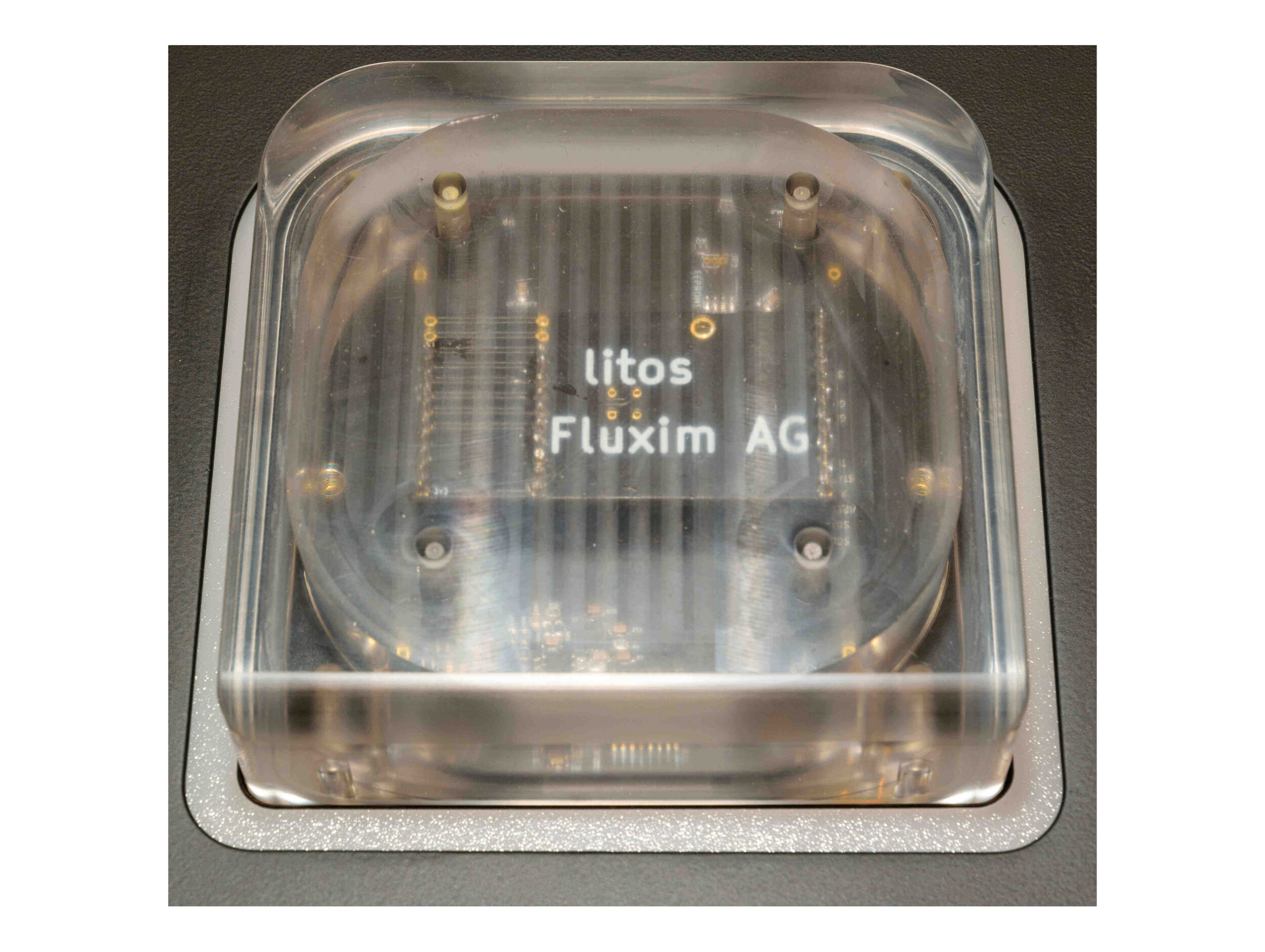

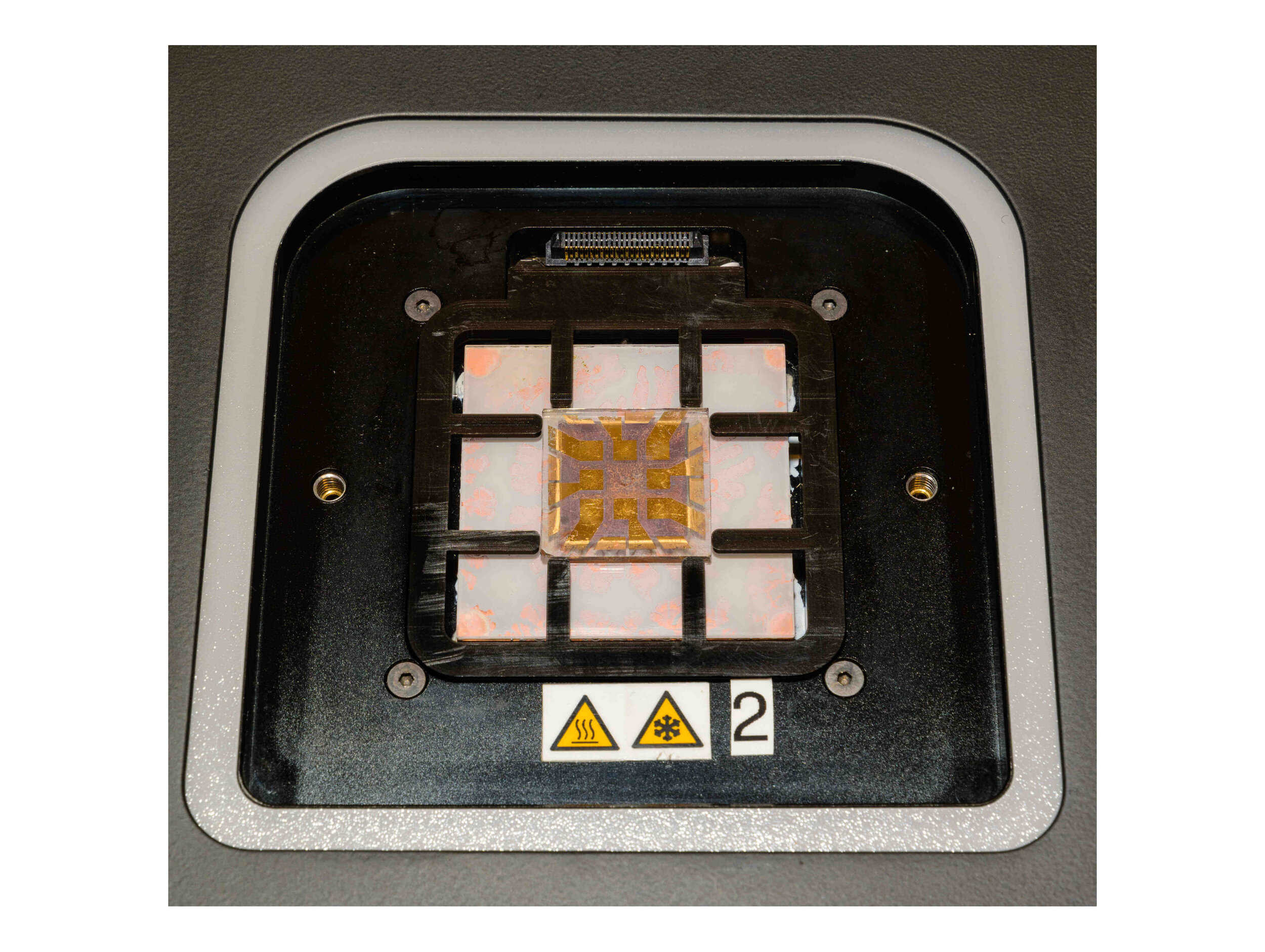

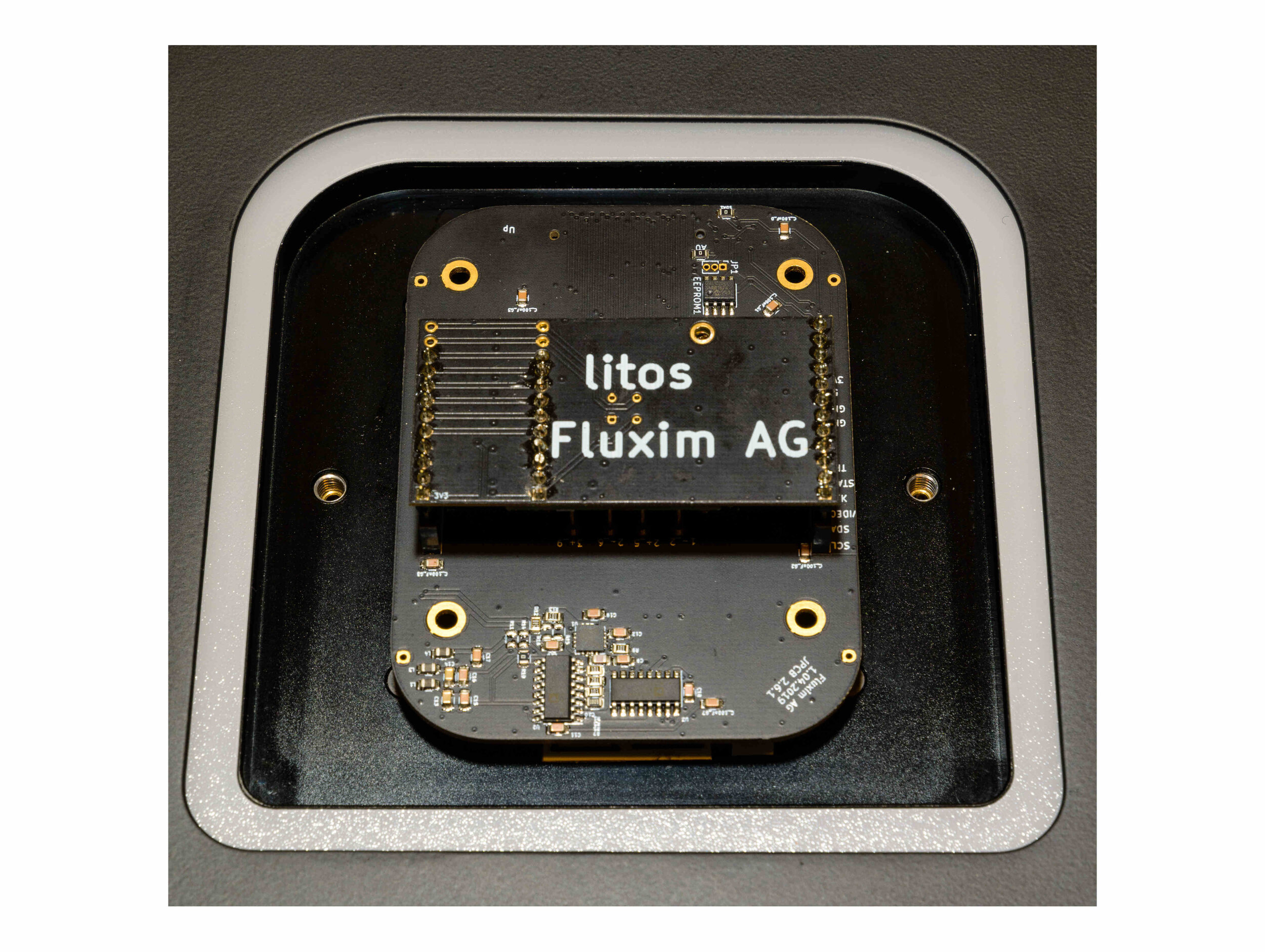

Sample Holder

Litos has 4 independent chambers to test simultaneously 4 samples with multiple pixels. The sample holders are custom-made according to the specific layout of our customers. Multiple boards with different layouts can be delivered. The board can be quickly replaced in the testing chamber by the user. Depending on the selected configuration, up to 8 solar cells or LEDs can be stressed individually in each chamber (32 solar cells in total).

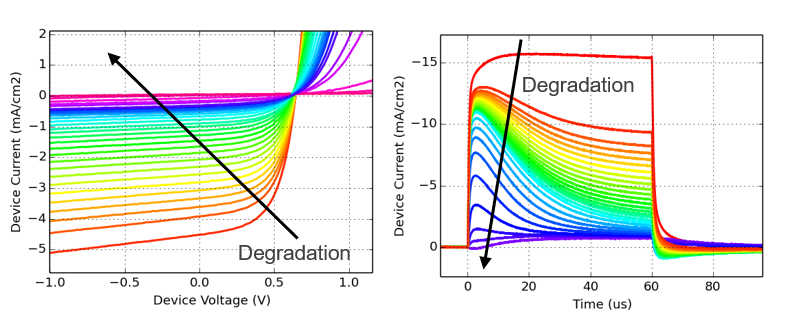

Litos/Paios Integration

Paios and Litos can be connected and managed by the same software (Characterization Suite). Full characterization of the device stability can be automatically performed in situ:

-

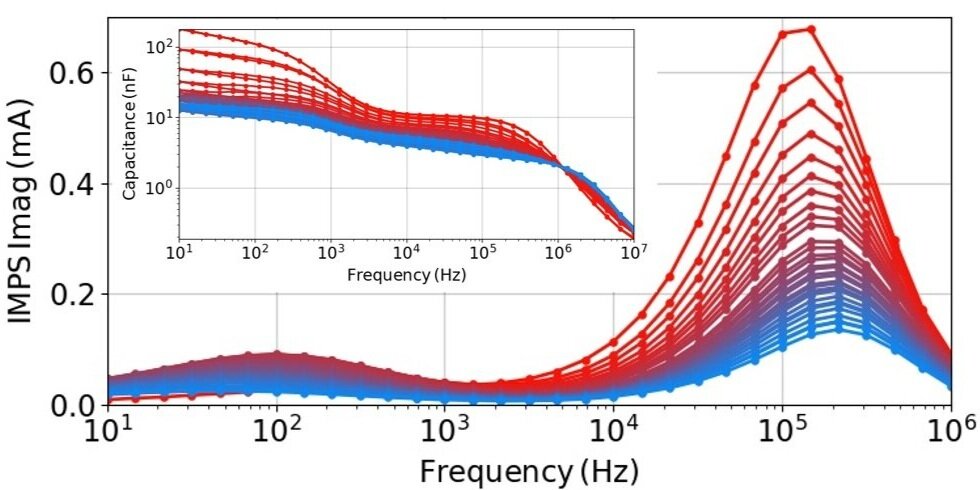

Understanding the degradation mechanisms of solar cells and LEDs with an automated routine of stressing and analysis.

-

Current-Voltage (I-V) characteristics.

-

Transient measurements (CELIV, TPV, TPC, TEL …)

-

Impedance spectroscopy / CV / IMPS / IMVS.

-

All measurements can be performed as a function of the temperature ( 0°C to 85°C).

Atmospheric Control Module (Under Development)

A complete solution to engineer the atmosphere inside the chambers and perform degradation analyses under different environmental conditions. PPM precision for both oxygen and water:

-

Nitrogen and dry air generator

-

Connection to each chamber. All chambers are in the same atmospheric conditions.

-

1 water bubbler.

-

Precision O2/N2 sensor and 3 mass-flow controllers.

-

1 Control unit for mass-flow controllers integrated. It can connect any gas to the mass-flow controller