Physical Vapour Deposition

3 products

3 products

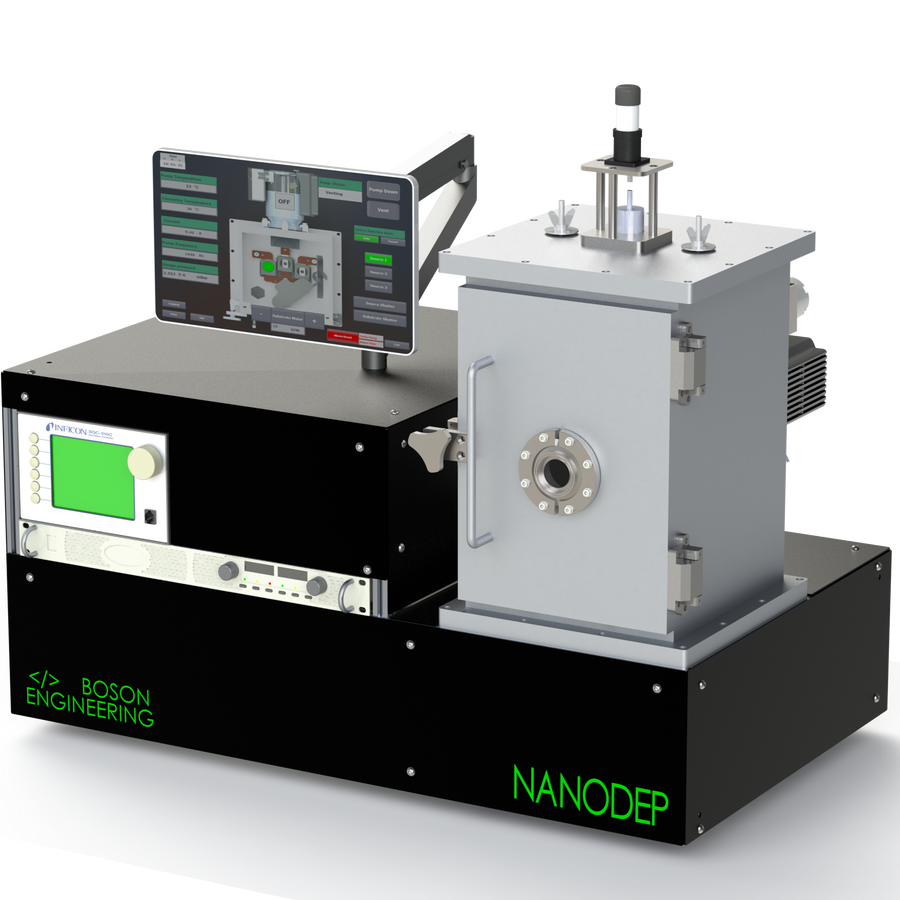

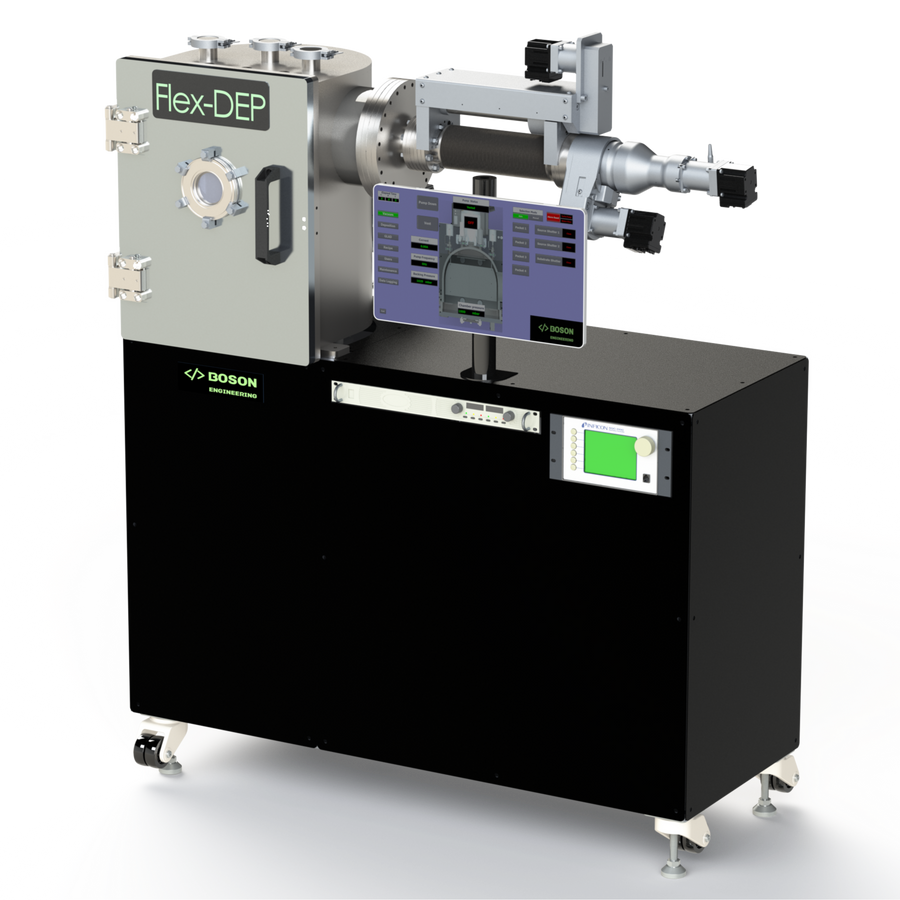

Nano Vacuum offers flexible, modular PVD (Physical Vapour Deposition) systems for high-quality R&D and pilot-scale production. These systems provide superior high-vacuum coating performance. All systems have modular designs, providing the flexibility to address a huge range of customer requirements.

In addition to thin-film deposition, our systems can also be fitted with complementary techniques such as ion beam sources, etching components and annealing stages.

We specialize in custom solutions! Call us to discuss your needs today.

Techniques:

Nano Vacuum tools can be fitted with all major PVD techniques:

It is possible to fit multiple techniques on-board a single system.

We also offer a variety of substrate stage options (heating; cooling; bias; etching; rotation; etc.), and can incorporate most third-party vacuum components.

For more information contact us today!

Subscribe today to hear first about our new and exciting technology