THE MASKLESS DIRECT IMAGER FOR HIGH-ACCURACY AND HIGH-RESOLUTION MICROSTRUCTURES

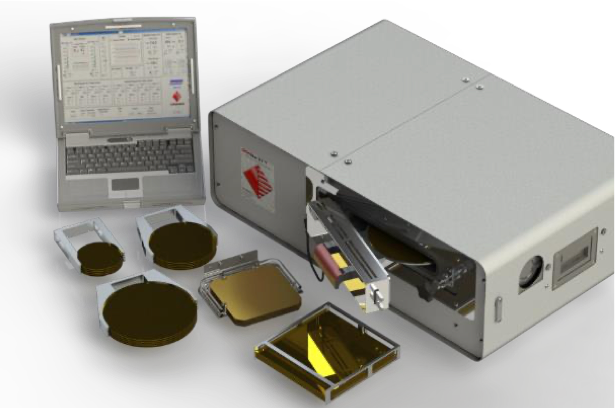

The VPG 300 DI is a Volume Pattern Generator specially designed for direct writing high-resolution microstructures in i-line resists. Derived from the mask making tool, it features all advanced VPG+ system components to be able to write with the highest precision and accuracy. The maximum write area covers a 300 mm wafer.

The target usage of the VPG 300 DI system is primarily in academic and industrial research and development, where high flexibility and features smaller than 2 µm are required. This system caters to the needs of various applications, including product prototyping, MEMS, mix and match with other tools, and writing of structures with quasi-stitching-less unlimited die sizes. The VPG 300 DI performance is comparable to a mask-based i-line stepper that is traditionally used for these applications, while providing the advantages of a maskless patterning technology.

Similar to the VPG+, the VPG 300 DI is based on the same field-proven ultra-high-speed exposure optical engine. However, it goes a step further by incorporating additional advanced system components such as a Zerodur® stage, differential interferometer, and various options for metrology, alignment, and wafer handling.

This combination of performance, technological benefits, and components makes the VPG 300 DI an ideal choice for researchers and developers seeking precise and efficient microstructure fabrication capabilities.