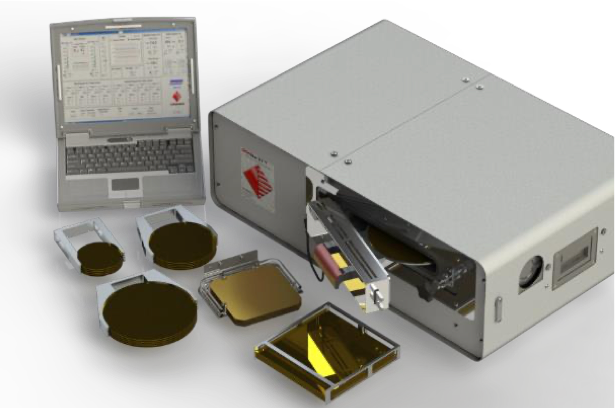

FineXT 6003

- In stock, ready to ship

- Backordered, shipping soon

-

Estimated Leadtime = days

Your inquiry was submitted successfully. You can expect to hear from us shortly.

The modular design allows to configure this production die bonder for multiple advanced packaging technologies. The machine’s capabilities can be easily enhanced to adapt to new technological trends in semiconductor manufacturing. Combined with an automatic material handling and tool management system, this ensures the production die bonder’s high degree of process flexibility for next-generation optoelectronic and demanding fan-out applications.

In operation, a speed mode and a precision mode can be flexibly combined. Given the frequently changing precision requirements during the assembly of multi-chip modules, this capability ensures optimal throughput and makes the production die bonder FineXT 6003 the perfect solution for modern semiconductor manufacturing environments.

*depending on configuration

Download the brochure here

Subscribe today to hear first about our new and exciting technology