3D surface metrology - fast, flexible, accurate and contact-free

The MicroProf® - 3D surface measurement technology for all measurement tasks. With the third generation of multi-sensor surface measuring devices, FRT is at the forefront of the market.

The MicroProf® enables for a wide range of measurement tasks which can be carried out quickly, efficiently and intuitively. As an established standard measuring device in modern 3D surface measurement technology, the MicroProf® has impressed our customers for many years for example in the semiconductor, medical and automotive industries. They are also at home in the MEMS/NANO/MST, sapphire, photovoltaic, engineering, optics and packaging industries.

Whether you want to measure the topography, the total thickness or the film thickness of your samples without contact, the versatile MicroProf® can be used universally due to the proven optical multi-sensor technology. Various optical measurement methods, which are only available as individual solutions elsewhere, have been combined into a universal, space-saving device. Depending on your requirements, the MicroProf®allows you to perform quick overview measurements of the entire sample, as well as high-resolution detail measurements down to the sub-nm range. This is made possible by the individual combinations of the sensors. Maintain flexibility for your future measurements and retrofit sensors easily and quickly, saving space, time and costs.

The MicroProf® series is the universal surface metrology tool for the fast and easy determination of topography, roughness and layer thickness.

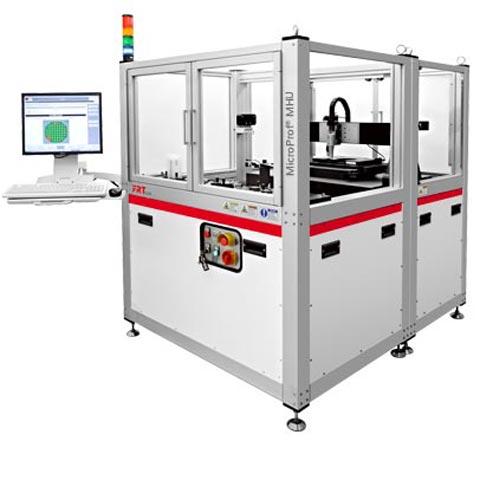

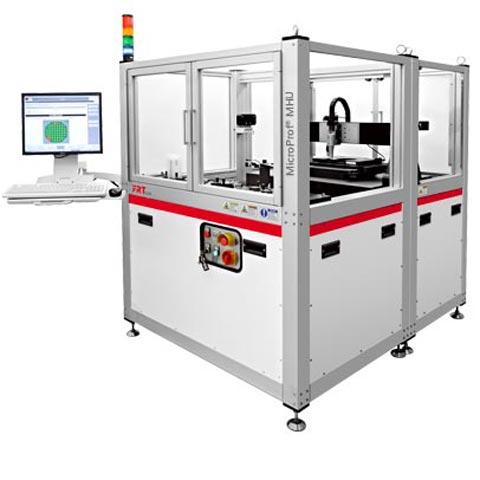

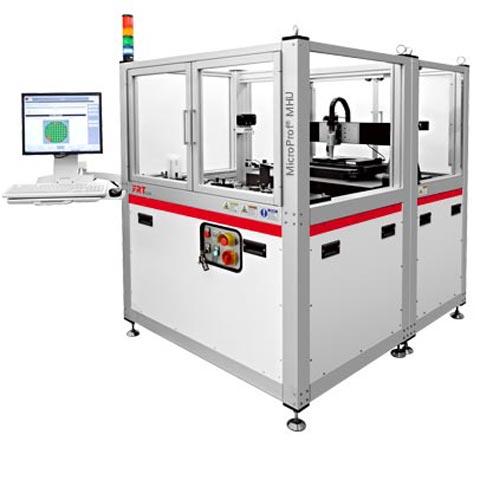

Many industrial applications require fully-automated measurements with high throughput. This, in turn, requires automatic handling of the samples. The MicroProf® MHU has been specially designed for the semi-conductor, MEMS and LED industry and can be easily configured for various sample (wafer) types. The handling unit can handle wafer sizes between 2 and 12 inches. Depending on the configuration, up to four cassettes can be processed simultaneously.

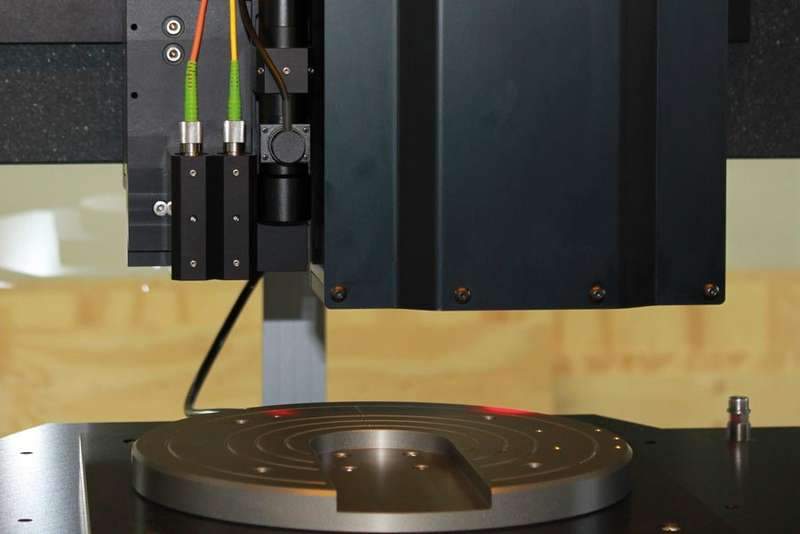

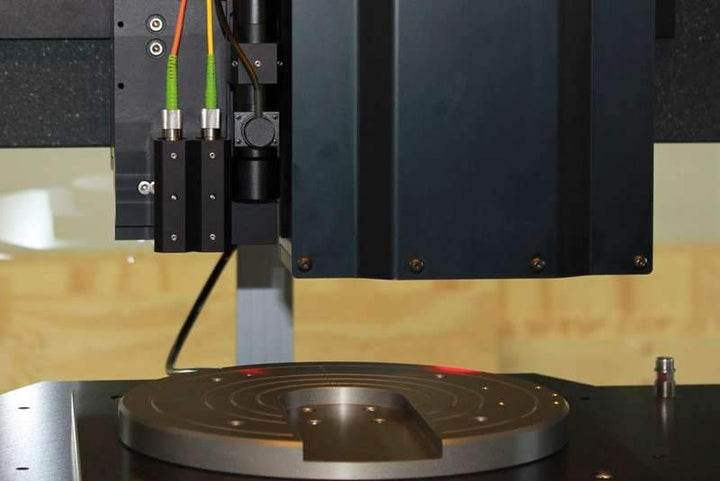

Both the tabletop and standalone MicroProf® series include the option for two-sided sample inspection. This enables for measurement of the top and bottom side of the sample simultaneously and determination of the sample thickness. The total thickness variation (TTV) of the sample can be determined along with the surface parameters, e.g. the roughness, waviness and flatness of both surfaces. The TTV option can be easily retrofitted on site.

Highlights MicroProf® MHU

- Material Handling Unit with twin-arm robot

- High throughput, up to 200 w/h

- Loading station for open cassettes

- OCR reader / Pre-aligner

- Sorting function for the separation of good and bad samples

- Optional SECS/GEM interface

- TTV option for double-sided measurement

Download the MicroProf® MHU datasheet here

Download the MicroProf® Family Overview brochure here