Evolved Compact Dicing Saw

- Φ150 mm

- Single spindle

Focus on Functionality and Expandability

DAD3231, designed for high performance and expandability, just like the conventional DAD3230, satisfies a wide range of needs, including electronic component materials such as glasses and ceramics. Because the equipment layout was designed with additional space, DAD3231 can support workpieces up to 6 x 6 inches as an option. This makes flexible processing of user-specified workpieces possible. A linear scale can be installed on the Y-axis as an option when high-accuracy processing is required.

Compatible with Diverse Small Workpiece Processing Needs

DAD3231 has a smaller footprint compared to existing equipment. The axis speed is accelerated and throughput is improved by adopting servo motors for all axes. In addition, this model uses PC electric components as standard and supports communication control as an option. Because image recognition functions, such as auto alignment, auto focus, auto kerf check, are installed as a standard specification, it is possible to minimize operator labor costs. A 2.0 kW high-torque spindle is installed as a standard specification.

Improved functions and operation

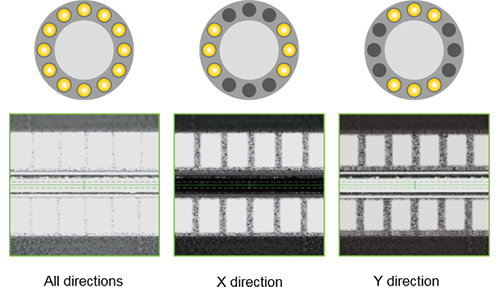

The high-speed, high-accuracy NCS (Non-Contact Setup, optional) reduces blade height measurement time for the processing table by 74%. Further processing quality stabilization is achieved through improved measurement accuracy. In addition, the visibility during kerf check was improved by enabling microscope ring light three-channel switching. This model supports SECS/GEM.

Ease of operation

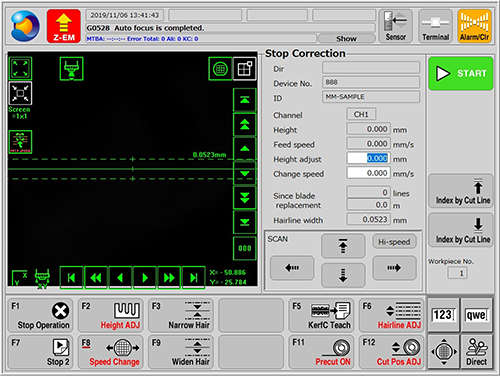

- XIS (Extended Interface System)

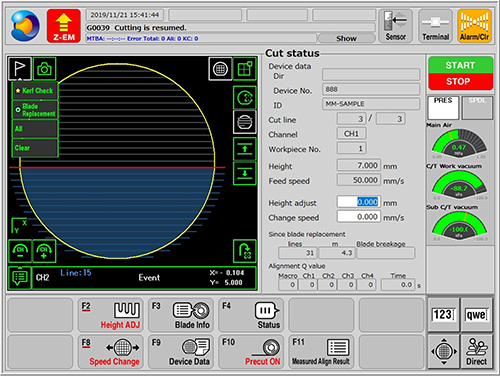

Operation buttons are consolidated on the microscope screen. - Wafer mapping

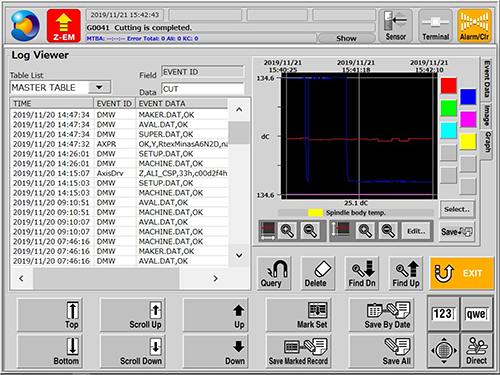

The processing status is displayed visually in the same way as fully automatic equipment. - Log viewer

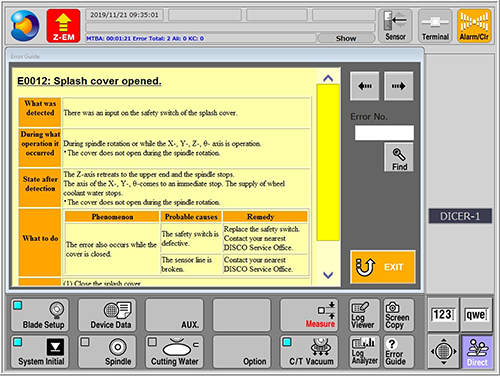

Analog data is displayed in a graph and equipment data is more easily visualized. - Help viewer

Troubleshooting is displayed when an error occurs to achieve quick and accurate recovery support. - Automatic alignment, Autofocus, Automatic kerf check

Specifications

| Specification | Unit | ||

|---|---|---|---|

| Max. workpiece size | - | Φ6 inch (150 mm × 150 mm optional accsessory) | |

| X-axis | Cutting range | mm | 210 |

| Cutting speed | mm/s | 0.1 ~ 800 | |

| Y-axis | Cutting range | mm | 162 |

| Index step | mm | 0.0001 | |

| Index positioning accuracy | mm | 0.005/185 (Single error) 0.003/5 |

|

| Y-axis scale (option) 0.002/185 (Single error) 0.001/5 |

|||

| Z-axis | Max. stroke | mm | 31.2(Φ2 inch blades) |

| Moving resolution | mm | 0.000002 | |

| Repeatability accuracy | mm | 0.001 | |

| θ-axis | Max. rotating angle | deg | 320 |

| Spindle | Layout | - | Single |

| Rated output | kW | 2.0 at 40,000 min-1 | |

| Rated torque | N・m | 0.48 | |

| Rotation speed range | min-1 | 3,000 ~ 40,000 | |

| Equipment dimensions(W × D × H) | mm | 650 × 950 × 1,670 | |

| Equipment weight | kg | Approx. 550 | |

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.