Fully Automatic Heavy Wire Wedge Bonder

Bondjets BJ955 and BJ959 belong to the new generation of ultrasonic wedge-wedge bonders developed for the fully automated processing of a wide range of large-sized substrates, chips and other materials.

The systems can be used as a fully automatic machine or operated manually. Hesse offers the only available solution on the market of handling wires from 50 μm up to 600 μm** with only one bondhead.

Bondjet BJ955/959 are characterized by several new features:

- Optimized pattern recognition

- Software features for the growing demand of connectivity and industry 4.0 (e.g. Hesse Bonder Network, remote control of PR, improved MES integration, …)

- Hesse Assist Tools: load cell, bondtool and wire spool detection, tool calibration without wedge gauge for operator independency Outstanding features are high speed and the largest bonding area.

A change from aluminium to copper can be realized within minutes. The Hesse GmbH, as technology leader, has designed the only heavy wire bondhead with a non destructive pulltest and a unique transducer integrated sensor for 100 % quality monitoring in real time. Advanced features available on the Bondjet BJ955 and BJ959 are designed to meet your present and future requirements and greatly enhance productivity. In addition to a standard configuration Hesse offers automation concepts individually adapted for every application.

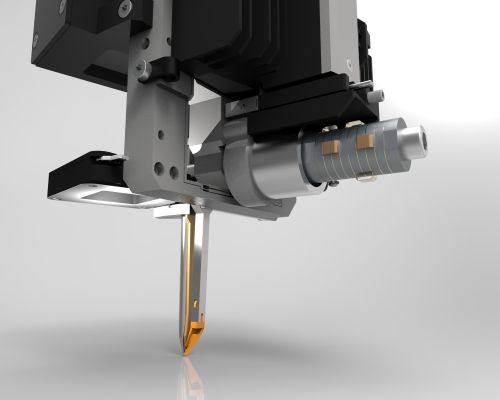

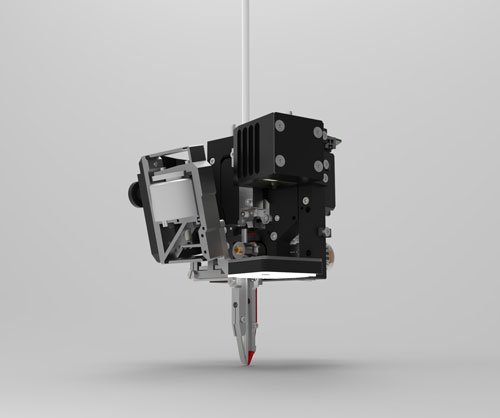

Heavy Wire Bondhead

Benefits and Features

Advanced features and process advantages

- 50 μm – 600 μm** bondhead for Al, Cu, AlCu (2 mil – 24 mil)

- Improved wire handling: short distance between bondhead and spool

- Optimized pattern recognition: image capture with new digital image processing and flash

- Hesse Assist Tools (option):

- E-Box: patented solution for optimized tool change and programmable alignment marks for cutter, wire guide and bond wedge

- Automated bondforce calibration; a load cell prevents operating error and ensures robust processes

- Innovative bondtool detection

- Wire spool detection

- Automated bondtool calibration without wedge gauge

- Precisely programmable bondforce actuator

- Loop generator for individual loops

- Wear-free components with Piezo technology

- Maintenance-free solid state joints

- Pre-setting of bondheads via EEPROM

Flexibility

- Working area:

- BJ955: 305 mm x 410 mm

- BJ959: 370 mm x 560 mm

- Flexible use of the large working area, e.g. vacuum clamping of several 5″ x 7″ standard DCBs

- Maximization of throughput by automation (two/more parallel lanes

Bondhead for Ribbon

Quality

- Continuous real time monitoring of wire deformation, transducer current and frequency within programmable control limits

- Process integrated Quality Control PiQC: detection of further parameters by additional sensor system (e.g. friction) for 100 % quality monitoring in real time (patented); as option

- Remote pull function on PiQC threshold value for optimized cycle time; up to 30 % save on equipment

- Integrated, non destructive pulltest for wire and ribbon

Heavy wire bondheads

- Heavy wire and ribbon bondheads for Al, Cu and AlCu

- An intelligent bondhead connecting system with integrated memory stores all calibration data and enables bondhead replacement in a few minutes

- Wire clamp for loop shape control is standard on all bondheads; optionally equipped with non destructive pulltest

Technical Data

Working area

- BJ955: X: 305 mm; Y: 410 mm; Z: 42 mm

- BJ959: X: 370 mm; Y: 560 mm; Z: 42 mm

- P-rotation: 440°

Mechatronic bondhead

- HBK (Frontcut, Backcut); frequency: 60 kHz*

- RBK Ribbon (Frontcut); frequency: 57kHz*

- RBK Copper (Frontcut, Backcut); frequency: 57kHz*

alternative Frequenzen auf Anfrage

Cutting methods

- active, passive, air cut (for frontcut)

Wire

- Al, Cu, AlCu: 50 μm – 600 μm** (2 mil – 24 mil)

Ribbon

- Al, Cu, AlCu: 250 μm x 25 μm bis 2000 μm x 400 μm** (Cu: 200 μm)

(10 mil x 1 mil up to 80 mil x 16 mil)

Ultrasonic

- Digital ultrasonic generator with PLL (Phase Locked Loop),

internal frequency resolution <1 Hz - Programmable ultrasonic power output

Footprint and weight

- BJ955: 740 mm x 1484 mm x 1912 mm (WxDxH, excl. light tower), appr. 1150 kg

- BJ959: 805 mm x 1634 mm x 1912 mm (WxDxH, excl. light tower), appr. 1300 kg

Various loop form functions

- Reproducible loop geometry by wire guide appropriate for the material involved and moving wire buffer

- Constant wire length and loop height

- Mechanically demanding loop geometrics by parameterization and individual wire clamp application

- Individual loop shapes by configurable loop trajectory generator

* exact range of frequencies on request

**depending on application and wire