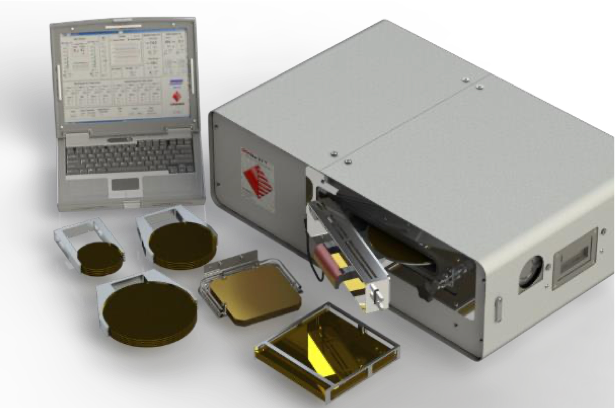

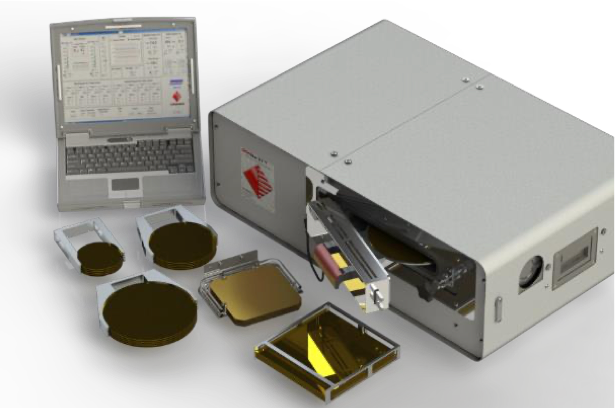

GEMStar XT family produces best in class ALD films from high aspect ratio particles through 200mm substrates both in single substrate and batch modes of operation

The GEMStar XT-S/D Thermal Atomic Layer Deposition system offers 300 °C (450 °C optional) ALD processing through the full range of substrates, including Solar Cell ALD development.

Configured standard with either a single (S) or dual (D) 200 °C manifold zones, four (S) or eight (D) high speed material ALD valve ports (one with vapor push technology), two locatable 200 °C material temperature zones and an external gas interface, the GEMStar XT-S/DTM represents one of the most configurable systems in its price range.

Key System Features

- Adjustable reactor temp up to 300°C

- Up to 200°C uniform gas distribution delivery

- Pulsed Vapor Push (PVPTM) to handle very low pressure material

- Selectable flow-through and exposure modes of deposition

- Substrate configurable end effectors up to 200 mm diameter substrates, batch cassette options as well as a heated platen

- User selectable carrier gas MFC controlled input up to 200 SCCM

- Field proven GEMFlowTM Control System

- Watchdog protection and EMO interface

- Operator touch safe exterior

Ease of Operation

The Arradiance GEMFlow Software provides complete user control over all key operating parameters such as temperature, gas flow rate, highspeed ALD valves, RF Power and vacuum isolation.

- Preloaded on business level Windows® Laptop User created processes can be saved enabling substrate to substrate and batch to batch consistency without sacrificing flexibility

- Diagnostic system and logging creates traceable data of all system parameters during operation

- Internal GEMStar XT USB control module

Serviceability

Modular ergonomic design with top panel access to all critical components

- Fast precursor changes and reconfiguration

- Easy access power, vacuum and gas connections

- Perfectly suited for glove box configuration

Specifications

| System Dimensions | 11” H x 32” W x 24” D designed to fit on desktop or lab bench |

| Door Mounted Substrate End Effector | Specify end effector diameter at time of order (200 mm default, 150 mm, 100 mm) Other sizes or batch cassettes available on request |

| Reactor/Door Thermal Zones | Two controllable zones up to 300 °C ± 1 °C 450 °C Processing available on request Material Manifold Single (S) or Dual (D) controllable manifold |

| Material Manifold | Single (S) or Dual (D) controllable manifold zones up to 200 °C Four (S) or eight (D) High Speed ALD Valve Controlled Material Ports Single Pulsed Vapor Push (PVPTM) Zone controlled by High Speed ALD Valve |

| Material Bottle Heated Zones | Up to four movable zones up to 200 °C |

| Material Bottles | Up to four or six (2 STD) DOT certified 150 ML Bottles with bellows sealed valves |

| External Gas Input | Single-S or up to four (2 STD)-D Input for external gasses such as optional Ozone |

| Inert Carrier Gas | Mass Flow Controlled up to 200 SCCM |

| Control System | GEMFlowTM Control Software Windows® Professional 64-bit Laptop GEMStar XTTM USB control module |

| Metrology Port | Spare KF-40 In Line metrology port for QCM or other customer needs Spare KF-25 Reactor port for other customer needs |

| Vacuum Gauge | Convection Vacuum Gauge |

The system is perfectly suited for glove box configuration.

GEMStar XT Options

GEMStar XT Systems offer many standard options to enhance system process and metrology capabilities. Most are easily field upgradeable. We also support custom requirements.

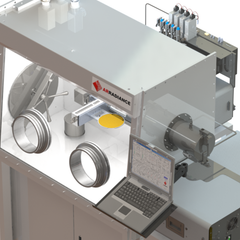

GEMStar XT Glovebox Integrated Systems

Custom designed for Arradiance by VTI, we offer single and dual station Gloveboxes supporting multiple GEMStar systems simultaneously offering both back and side mounted GEMStar systems

ARR-850880 Glovebox Interface

Working with leading manufactures like VTI, GEMStar XT easily interfaces to all suppliers

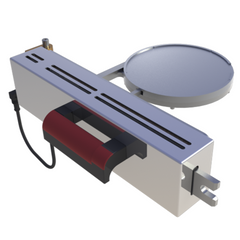

ARR-859000 Load Lock

Manual load lock system to degas samples before being introduced to the ALD reactor

ARR-40591B-DOT Material Bottles

130ML DOT4B Certified GEMStar Material Bottle compatible with all GEMStar Systems

Bottles can be filled by STREM Chemicals for most materials

ARR-850593 Material Heater Jackets

XT Systems have two material heater zones and can be upgraded to four zones with additional heater jackets

Batch Processing

Arradiance offers many options for batch processing

ARR-850600-6 450°C Heated Platen

Single wafer processing platen door for 150mm substrates

ARR-850600-SR/DR Particle Coating

Arradiance offers several options for particle coating

ARR-850402-KF25-GP

NW-25 ALD TPGP Vacuum Gauge Protector utilizing our patent pending TPGP technology

ARR-851850-C Quartz Crystal Monitor

Quartz Crystal Monitor Sensor, controller

Mounts directly to our standard KF-40 Metrology Port

Ozone Generator

Should your process require a water free film process, we offer a high-performance Ozone generator and hardware to allow injection though one of GEMStar XT’s external gas inputs.