CMP polisher designed to process hard-to-process materials such as sapphire and SiC

- Φ200 mm

- 1 axis, 2 chuck tables

- Wafer Thinning

- Stress Releaf

Fully automatic operation

The DFP8141 is a fully automatic polisher which performs CMP processing from cassette to cassette. With the installation of a cleaning station, wafer cleaning and drying after processing are performed automatically.

For small workpieces made of difficult-to-process materials

The DFP8141 supports CMP for materials such as sapphire, SiC, LT, and LN.

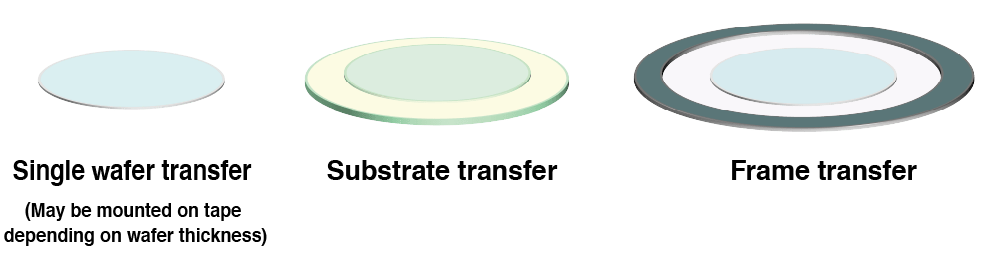

A transfer system which supports three workpiece configurations

The transfer system accepts three workpiece configurations: single wafer transfer, substrate transfer, and frame transfer.

Specifications

| Specification | Unit | ||

|---|---|---|---|

| Supported workpiece size | - | Φ8 inch | |

| Polishing method | - | CMP | |

| Polishing wheel | - | Φ300 mm CMP pad | |

| Spindle | Rated output | kW | 7.5 |

| Rotation speed range | min‐1 | 500 ~ 2,000 | |

| Equipment dimensions (W x D x H) | mm | 900 x 2,584 x 2,000 | |

| Equipment weight | kg | Approx.3,100 | |

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.

You may also like

More from DISCO

Recently viewed