Dry polisher for Φ8-inch wafers with chemical free stress relief

- Φ200 mm

- 1 axis, 1 chuck table

- Wafer Thinning

- Stress Releaf

Improved yield for thin wafers

This dry polisher can remove grinding damage layer on the backsides of wafers up to Φ8 inches without slurry. This process greatly reduces wafer breakage and warpage and improves die strength and product yield. In addition, it contributes to reducing environmental impact.

In-line system

DFP8140’s design allows it to be integrated or retrofitted with DISCO grinders. Safer wafer transferring can be achieved when installed inline with DFG8540 (option).

Environmentally friendly process

The dry polishing process does not require chemical processing through wet etching or CMP. Dry polishing with DFP8140 is environmentally friendly while maintaining a lower cost of ownership than other stress relief processes.

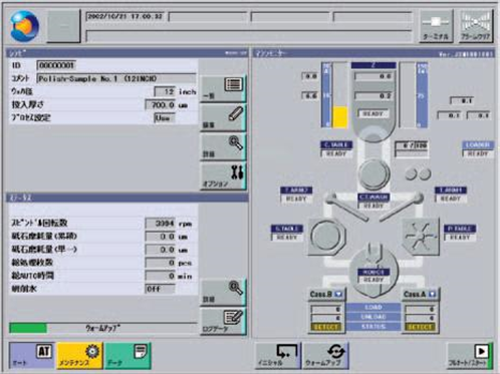

Easy operation

Installation of a touch screen and GUI (Graphical User Interface) provides improved operability. In addition, processing and equipment status are displayed on-screen and each operation can be performed just by touching the icons. Thus, high operability during processing and maintenance is achieved.

Specifications

| Specification | Unit | DFP8140 | |

|---|---|---|---|

| Supported workpiece size | - | Φ4/5/6/8 inch(Select one size) | |

| Polishing Method | - | Anomalous In-feed grinding with wafer rotation | |

| Wheel | - | Φ300 mm Dry Polishing Wheel | |

| Chuck table type | - | Porous chuck table | |

| Chuck-method | - | Vacuum | |

| Number of revolutions | min‐1 | 0 ~ 300 | |

| Chuck table cleaning | - | Water & air thrust up, Leveling stone and brush cleaning | |

| Spindle | Rated output | kW | 4.8 |

| Rotation speed range | min‐1 | 1,000 ~ 4,000 | |

| Internal load sensor | - | Thin force sensor | |

| Spinner unit | - | Wafer washing and drying by atomizing nozzle | |

| Equipment dimensions (W×D×H) | mm | 1,200 × 2,670 × 1,800 | |

| Equipment weight | kg | Approx.1,900 | |

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.