Automatic grinder to respond to new processing needs

- Φ200 mm

- 1 axis, 1 chuck table

Simple and compact single-axis grinder

The DAG810 is a compact, automatic grinder for workpieces up to 8" in diameter. It has one spindle and one chuck table and is designed to process a variety of materials.

Space-saving design

Equipment dimensions: 600 (W) x 1,700 (D) x 1,780 (H) mm

Precision grinding

Adoption of high-rigidity, low-vibration spindle provides superior grinding results and is capable of in-feed grinding and creep feed grinding (user-specified specification).

Unlimited materials

Process hard or brittle substrates of various diameters with ease. The DAG810 is also the choice for processing a wide variety of electronic components.

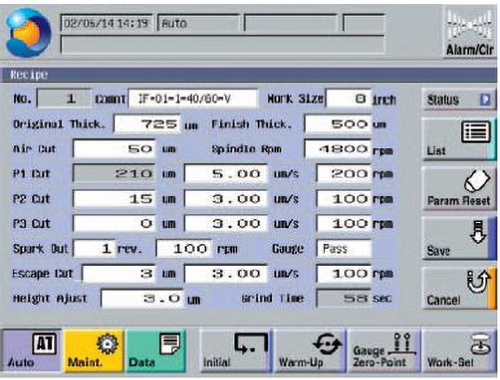

Easy operation

Installation of a touch screen and GUI (Graphical User Interface) provides improved operability. In addition, processing and equipment status are displayed on-screen and each operation can be performed just by touching the icons.

Special options for a variety of needs

- Height gauge

One or two-probe height gauge (option) - In-feed grinding

Workpieces up to Φ300 mm (option) - Frame grinding

8" frame grinding (option) - Creep-feed grinding

Workpieces up to Φ200 mm (user-specified spec.)

High-precision applications

- Processes silicon and compound semiconductors for analysis.

- Grinds resin for CSP and WL-CSP

- Improves the planarity of lithium tantalate and lithium niobate

- Processes green ceramics and sapphire

Specifications

| Specification | Unit | ||

|---|---|---|---|

| Supported workpiece size | - | Φ8 inch (Φ4, 5, 6, 8 inch with universal chuck table use) |

|

| Grinding Method | - | Anomalous In-feed grinding with wafer rotation | |

| Grinding Wheels | - | Φ200 mm Diamond Wheel | |

| Spindle | Rated output | kW | 4.2 |

| Rated torque | N・m | 5.9 | |

| Rotation speed range | min‐1 | 1,000 ~ 7,000 | |

| Equipment dimensions (W × D × H) | mm | 600 × 1,700 × 1,780 | |

| Equipment weight | kg | Approx.1,300 | |

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.