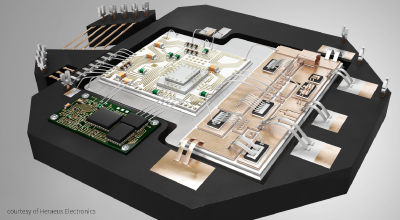

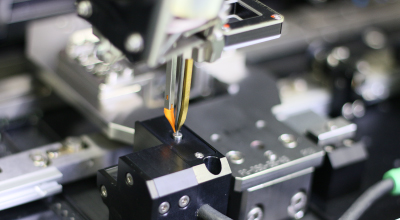

The Bondjet BJ931 is an ultrasonic wedge bonder developed especially for maxtrix leadframe applications. The application of two bondheads enables to bond two different wire sizes as well as a combination of wire and ribbon.

The fully automatic dual-head leadframe wedge bonder Bondjet BJ931 meets the latest technology and flexibility demands for automotive and power electronics applications; handling heavy aluminum, copper wire and ribbon on two specialized bondheads that can be exchanged.

Your benefits:

- Robust, clean design

- Low maintenance requirements

- User-friendly software

- Service support functions

- Industry-leading PiQC™ process monitoring system

Features and Process Advantages

- Precisely programmable bondforce actuator

- Wear-free components with Piezo technology

- Maintenance-free solid state joints

- Integrated, non destructive pulltest for wire and ribbon

- Automated bondforce calibration

- Pattern recognition time: 6 ms – 8 ms (search region: 512 × 512 pixels, pattern: 64 × 64 pixels)

- Rapid image capture with new digital image processing and flash light illumination

- E-Box: patented solution for optimized tool change and programmable alignment marks for cutter, wire guide and bond wedge

- Speed: Highest UPH due to linear motors for bonder and indexer

Central wedge bonder control system

- A central 23″ touch panel is used to monitor and control the bonder and indexing system

- Metal keypad and robust trackball for industrial use

- User-friendly calibration wizard and automatic update of calibration data at bondhead change on all available bondheads

Automotive Module

Quality

- Continuous, real time monitoring of wire deformation, transducer current and frequency within programmable control limits

- Process integrated Quality Control PiQC: detection of further parameters, e.g. friction behavior, by additional sensor system for 100 % quality monitoring in real time (patented); as option

- Remote pull function on PiQC threshold value for optimized cycle time; up to 30 % save on equipment

- Integrated, non destructive pulltest for wire and ribbon

Technical Data

E-Box

Mechatronic bondheads

- Heavy wire and ribbon bondheads for Al, Cu and AlCu:

- HBK (Frontcut, Backcut); Frequency: 60 kHz*

- RBK Ribbon (Frontcut); Frequency: 57 kHz*

- RBK Copper (Frontcut, Backcut); Frequency: 57 kHz*

alternative frequencies available on request

- Cutting methods: active, passive, air cut (for frontcut)

- Digital ultrasonic generator with PLL (Phase Locked Loop),

internal frequency resolution <1 Hz; programmable ultrasonic power output - An intelligent bondhead connecting system with integrated memory stores all calibration data and enables bondhead replacement in a few minutes

- Wire clamp for loop shape control is standard on all bondheads;

optionally equipped with non destructive pulltest - Option: Inline pull modules: up to 4 modules per bondhead for a non-destructive pulltest (up to a total of 8 per system)

Wire

- Al, Cu, AlCu: 50 μm – 600 μm** (2 mil – 24 mil)

Ribbon

- Al, Cu, AlCu: 250 µm x 25 µm up to 2000 µm x 400 µm**

(Cu: 200 µm) (10 mil x 1 mil up to 80 mil x 16 mil)

Loop form functions

- Reproducible loop geometry by wire guide appropriate for the material involved and moving wire buffer

- Constant wire length and loop height

- Mechanically demanding loop geometrics by parameterization and individual wire clamp application

- Individual loop shapes by configurable loop trajectory generator

High speed leadframe indexer

- Strip dimensions :

100 mm – 280 mm length, 15 mm – 90 mm width,

max. 3.0 mm down-set - Substrate types: TO220, SOIC, SO8, SOL8, SOT, SOT23, SC70, power-QFN, QFN, DPAK, DFN, DSO, COB, multi-lead SOP, matrix L/F, flat-boat, programmable pitch etc.

- Index time: 100 ms for typical TO220 device (includes clamping)

- Magazine size: 115 mm – 285 mm length, 20 mm – 100 mm width,

50 mm – 200 mm height

Working area

| Bonder | X | Y | Z |

| BJ931 | 100 mm | 90 mm | 42 mm |

P-rotation: 440°

Footprint and weight

| Bonder | W x D x H [mm] | Weight |

| BJ931 | 1550 – 1725 x 1273 x 1885 | ca. 1400 kg |

| excl. attached parts like e.g. status lamp, control panel etc. | ||

Media connectivity

- Power supply 230V AC

- Gigabit-Ethernet (TCP/IP)

- USB-Ports

- HDMI

- Compressed air (CDA clean, dry air)

- Vacuum

- exact range of frequencies on request

**depending on application and wire

You may also like

More from Hesse Mechatronics

More from Wire & Die Bonders

Recently viewed