The Bondjet BJ855 is the latest generation of fully automated fine wire bonders and expands the existing product portfolio of fine wire bonders. The Bondjet BJ855 is characterized by the following features:

- Wedge-wedge and ball-wedge bondheads

- Optimized pattern recognition (PR)

- Software features for the growing demand of connectivity and industry 4.0 (e.g. Hesse Bonder Network, remote control of PR, improved MES integration, …)

- Hesse Assist Tools: load cell, bondtool detection, bondtool calibration without wedge gauge for operator independency

The Bondjet BJ855 meets the increasing demands of wire bonding and contributes to easy porting through smart functions such as the bondhead memory or the chip libraries. Typical applications for wire wire bonders are components in HF and RF technology, COB, MCM, hybrids, optical and automotive electronics. In addition to a standard configuration, Hesse offers automation concepts individually adapted for every application.

The wire bonder Bondjet BJ855 defines the latest state of technological development compared to the competition and is benchmarked for:

- The fastest bonding speed in the industry

- The largest working area

- The greatest axis accuracy

Benefits and Features

Advanced features and process advantages

- High precision touchdown detection without time delay, e.g. for bonding on very thin substrates

- Optimized pattern recognition: image capture with new digital image processing and flash

- Hesse Assist Tools (option):

- E-Box: patented solution for optimized tool change and

programmable alignment marks for wedge and wire clamp - Automated bondforce calibration; a load cell prevents operater error and ensures robust processes

- Innovative bondtool detection

- E-Box: patented solution for optimized tool change and

- Automated bondtool calibration without wedge gauge

- Loop generator for individualized loops

- Wear-free components with Piezo technology

- Maintenance-free solid state joints

- Pre-setting of bondheads via EEPROM

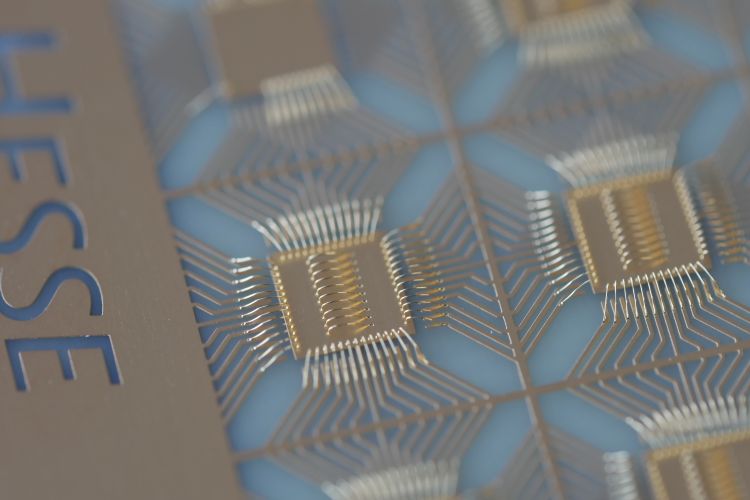

Fine wire (Au) with mit ball-wedge bondhead

Flexibility

- Flexible use of working area, e.g. with a number of bonding stations (manual loading or with indexers)

- Universal software interface for indexer control

- Maximization of throughput by automation with two or more parallel lines

Speed

- Up to 7 wires per second, depending on application and bondhead,

e.g. wedge-wedge bondhead, 25 μm wire, 1 mm loop length, metallized wafer

Quality

- Continuous real time monitoring of wire deformation, transducer current, frequency and impedance within programmable control limits

- Process integrated Quality Control PiQC: detection of further parameters, e.g. friction behavior, by additional sensor system for 100 % quality monitoring in real time (patented); available as an option

Wedge-Wedge bondhead for wire bonder Bondjet BJ855

- Bondhead 45°, 60° and 90° (deep access)

- Freely programmable wire feed, tail length, tear stroke and opening gap of wire clamp

- Precise bondforce control (static and dynamic)

- Bondheads can be replaced in minutes

Ball-Wedge bondhead for wire bonder Bondjet BJ855

- Multi-level bonding according to Z axis stroke of 31 mm

- 11/19 mm capillaries

- Ultrasonic in preferred direction by bondhead rotation

Ball-wedge bondhead for wire bonder BJ855

Technical Data

Working area

- X: 305 mm; Y: 410 mm

- Z stroke: 31 mm

- P rotation: 440°

Mechatronic bondhead

- Wedge-wedge bondhead 45°, 60°

- Wedge-wedge bondhead 90° (deep access) for ribbon or wire

- Ball-wedge bondhead

Wire

- Al, Au, Ag, Cu, Pt: 12.5 µm – 75 µm*(0.5 mil – 3 mil)*

Ribbon

- Al, Au: 35 µm x 6 µm up to 250 µm x 25 µm*

(1.4 mil x 0.25 mil up to 10 mil x 1 mil)*

Fine wire loop design

- Loop generator for individualized loops

- Loop form functions: constant wire length, constant loop height, individual loop shapes

- Fine pitch (wedge-wedge): 40 µm inline, 25 µm staggered/dual line (depending on wire diameter and loop)

Footprint and weight

- 740 mm x 1484 mm x 1912 mm (W x D x H , excl. light tower)

- Weight: approx. 1150 kg

* depending on bondhead, application, wire