Ultra compact dual-spindle automatic dicing saw

- Φ200 mm

- Facing dual spindle

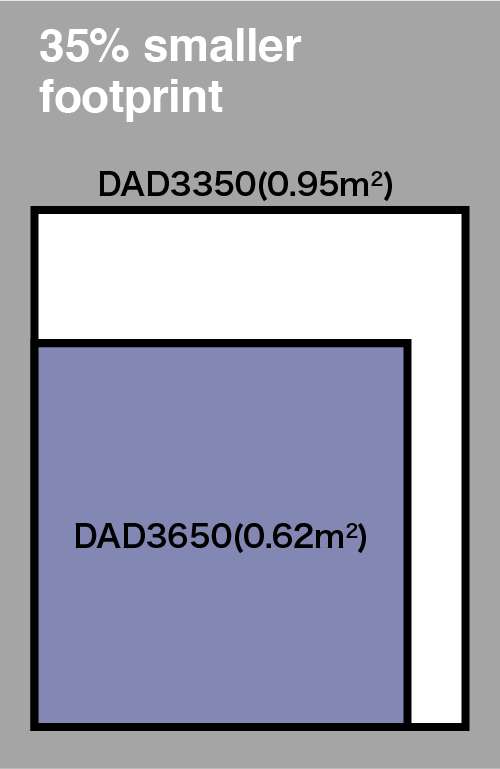

Small footprint

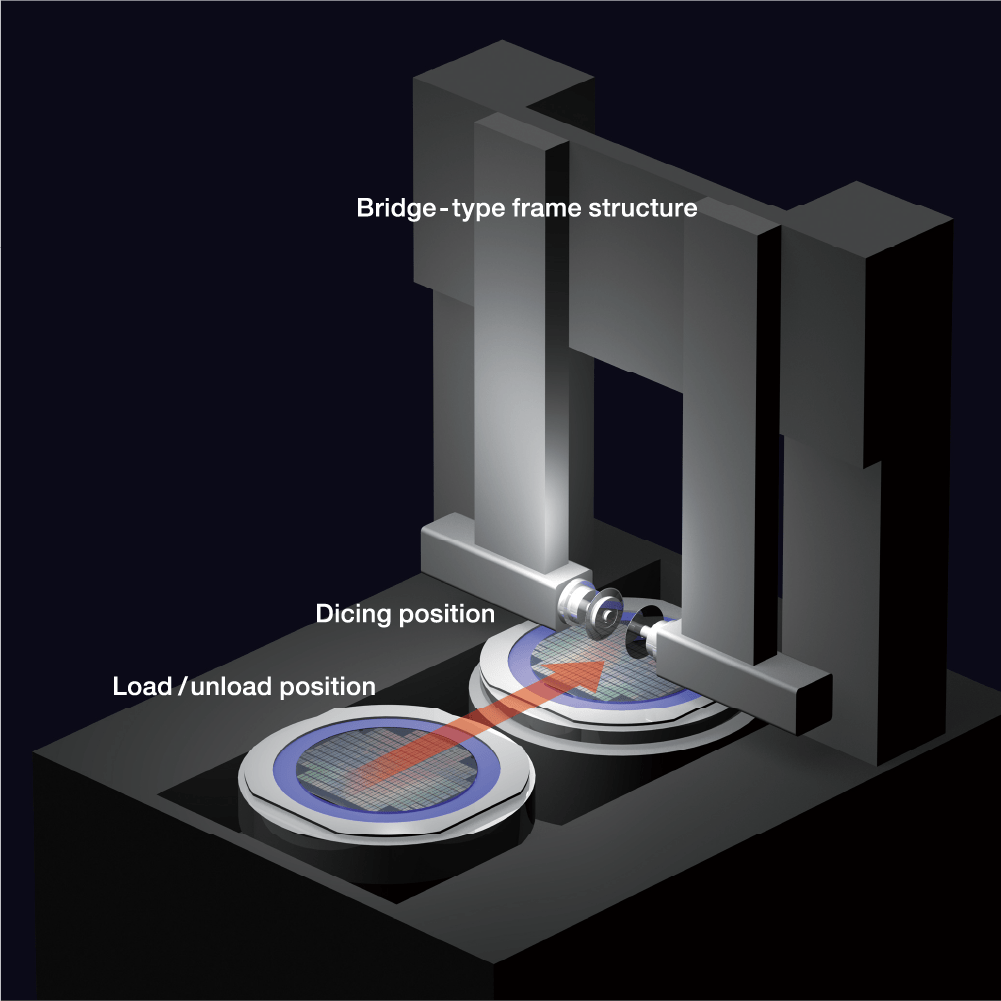

The optimal design of the DAD3650 combines high functionality and ultra compactness for a dual-spindle automatic dicing saw giving it a footprint 2/3 the size of the widely used single-spindle DAD3350 dicer for Φ8 inch wafers.

High throughput

By dicing with 2 spindles simultaneously in dual cut mode, high throughput of as much as twice that of a single-spindle dicer can be achieved.

High processability

While possessing a small footprint, the DAD3650 can be modified to support the same maximum workpiece size (max Φ8 inch, 250 mm sq.) as the DAD3350 with a user-specified specification. Also, by mounting a different blade on each spindle and using step cut to dice in 2 stages, it is possible to process workpieces requiring very high quality.

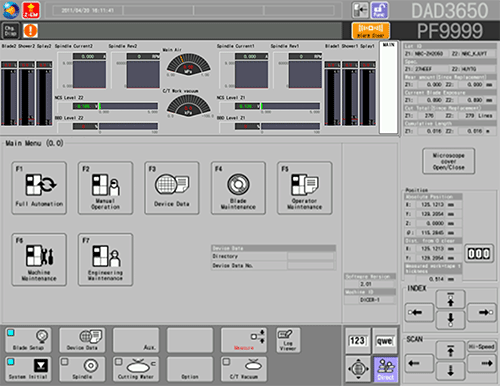

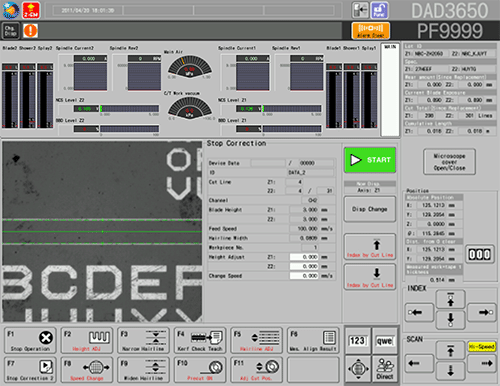

Enhanced ease of use

Intuitive operation is possible using the same GUI (Graphic User Interface) as DAD3350, the best selling manual dicing saw compatible with Φ8-inch workpieces. By adopting a 19-inch LCD touch panel, it is possible to operate the equipment and check the equipment and blade conditions at the same time. The operator’s labor load is reduced using the auto alignment function as a standard specification in addition to providing basic access for operation, replacement of workpieces and blades, etc. on the front side of the equipment.

Environmentally-conscious design

The DAD3650 is a green procurement compliant product * which means it does not contain the 15 hazardous chemical substances listed in the “List of DISCO Restricted Substances” and the six substances specified in the EU RoHS Directive.

* A green procurement compliant product refers to products that satisfy DISCO‘s green procurement standards and conforms to EU RoHS Directives.

Water conservation is made possible through the adoption of a newly developed, low heat generation spindle, which reduces cooling water consumption by half compared to existing equipment.

Specifications

| Specification | Unit | ||

|---|---|---|---|

| Max. workpiece size | - | Φ8 inch (250 mm × 250 mm, Φ300 mm user-specified specification) | |

| X-axis | Cutting range | mm | 260 |

| Cutting speed | mm/s | 0.1 ~ 1,000 | |

| Y-axis | Cutting range | mm | 260 |

| Index step | mm | 0.0001 | |

| Index positioning accuracy | mm | 0.002/260 (Single error) 0.002/5 |

|

| Z-axis | Max. stroke | mm | 32.2 |

| Moving resolution | mm | 0.00005 | |

| Repeatability accuracy | mm | 0.001 | |

| θ-axis | Max. rotating angle | deg | 320 |

| Spindle | Rated output | kW | 1.8 |

| Rated torque | N・m | 0.29 | |

| Rotation speed range | min‐1 | 6,000 ~ 60,000 | |

| Equipment dimensions(W×D×H) | mm | 790 × 790 × 1,890 | |

| Equipment weight | kg | Approx. 1,100 | |

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.