Offering improved productivity of fully automatic dual spindle dicing saws by introducing measures to increase throughput with proven records in the field

- Φ200 mm

- Facing dual spindle

Increased productivity

DFD6341 is the latest fully automatic dual spindle dicing saw for Φ8-inch wafers, incorporating the throughput enhancement technology developed in DFD6362 for Φ300 mm wafers. Adoption of a uniquely developed axis mechanism enables X-axis return speeds up to 1,000 mm/s. Improved acceleration and deceleration performance for each axis also increases the distance where the axis moves at maximum speed, substantially improving throughput. In addition, optimization of the parts used increases the speed of the major transfer unit and a shorter distance between the spindles allows for less processing time during dual cut.

Space - saving design

The footprint is reduced by 3% from the DFD6340. Four different accessories: the transformer, UPS (uninterruptible power supply), CO2 injector, and booster pressure pump can be included internally without expanding the footprint.

Easy operation

A GUI (graphical user interface) which has been recognized as easy to use on existing models has been included on the DFD6341.Combined with an LCD touch panel, the DFD6341 offers stress-free operation for operators.

High speed flash alignment (optional)

High speed flash alignment combines a xenon flash lamp and a high speed CCD shutter for high speed. Combines a xenon flash lamp and a high-speed CCD shutter to perform high speed alignment without the need to stop the chuck table, which reduces alignment time and increases throughput.

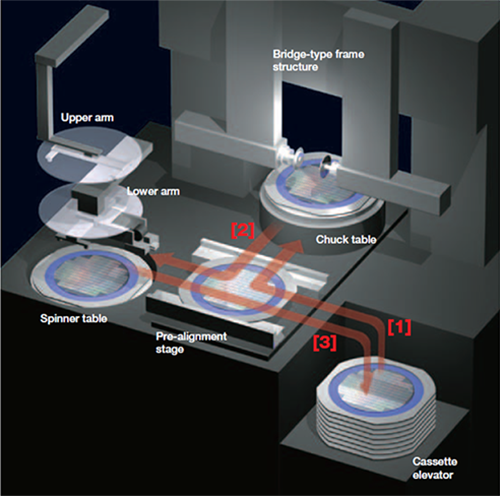

DFD6341 Operation flow

-

Lower arm moves workpiece from the cassette to the pre-alignment stage. Lower arm moves the workpiece to the chuck table → cutting →

-

Upper arm moves the workpiece to the spinner table → cleaning & drying →

- Lower arm returns the workpiece to the cassette

Specifications

| Specification | Unit | 1.2、1.8 kW、High speed rotation | 2.2 kW | |

|---|---|---|---|---|

| Max. workpiece size | - | Φ8 inch | ||

| X-axis | Cutting range | mm | 210 | |

| Cutting speed | mm/s | 0.1 ~ 1,000 | ||

| Y1・Y2-axis | Cutting range | mm | 210 | |

| Index step | mm | 0.0001 | ||

| Positioning accuracy | mm | Within 0.002/210 (Single error) Within 0.002/5 |

||

| Z-axis | Max. stroke | mm | 19.22 (For Φ2 inch blade) | 19.9(For Φ3 inch blade) |

| Moving resolution | mm | 0.00005 | ||

| Repeatability accuracy | mm | 0.001 | ||

| θ-axis | Max. rotating angle | deg | 380 | |

| Spindle | Rated torque | N・m | 0.19(1.2 kW/High speed rotation) 0.29(1.8 kW) |

0.7 |

| Rotation speed range | min‐1 | 6,000 ~ 60,000(1.2 kW/1.8 kW) 20,000 ~ 80,000(High speed rotation) |

3,000 ~ 30,000 | |

| Equipment dimensions(W×D×H) | mm | 1,180 × 1,080 × 1,820 | ||

| Equipment weight | kg | Approx. 1,500 | ||

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.