Highly expandability to support various processing needs

- Φ200 mm

- Single spindle

Supports a wide range of applications

DAD3351 is a semi automatic dicing saw compatible with Φ8-inch workpieces. Includes a high output 1.8 kW spindle as standard. Also, using a high torque, high rigidity 2.2 kW spindle (optional), difficult-to-process materials including silicon and ceramics can be processed. Through a user-specified specification, blades up to Φ5 inches can be used for processing. As a result, it is possible to process workpieces with thicknesses of 10 mm or more. Supports blades up to Φ5 inches with user-specified specification. In addition, the multi-alignment function is available as an option.

Stable processing quality

Adopted high bridge-type frame structure and moved the spindle support structure forward to minimize the effects of thermal expansion and vibration, providing a more stable processing point. In addition, a spindle temperature sensor was installed for temperature monitoring.

Processing Time Reduction

Processing time is decreased up to 5% compared to the existing equipment through axis-speed improvement by adopting servo motors for all axes and optimizing the control parameters.

Improved functions and operation

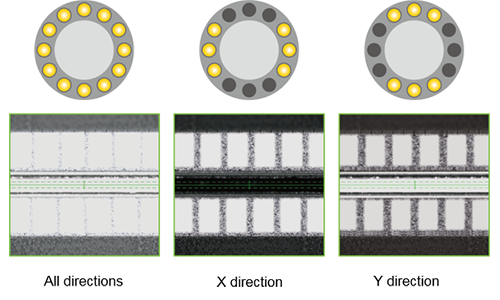

The high-speed, high-accuracy NCS (Non-Contact Setup, optional) reduces blade height measurement time for the processing table by 74%. Further processing quality stabilization is achieved through improved measurement accuracy. In addition, the visibility during kerf check was improved by enabling microscope ring light three-channel switching. This model supports SECS/GEM.

Easy operation

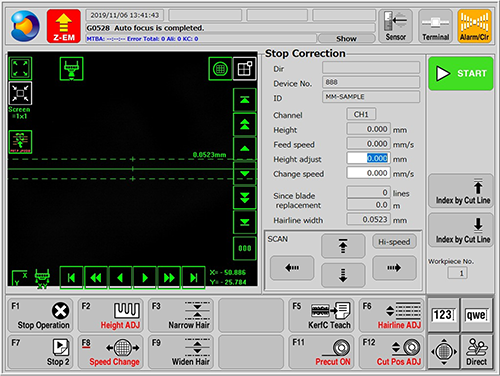

- XIS (Extended Interface System)

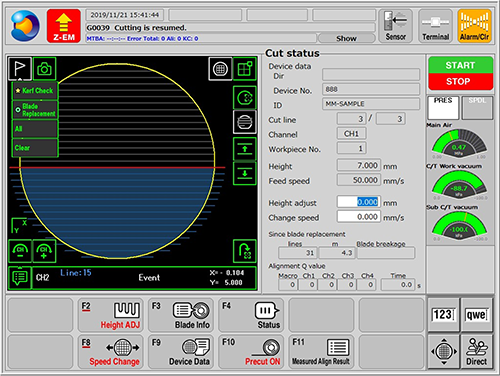

Operation buttons consolidated on microscope screens - Wafer mapping

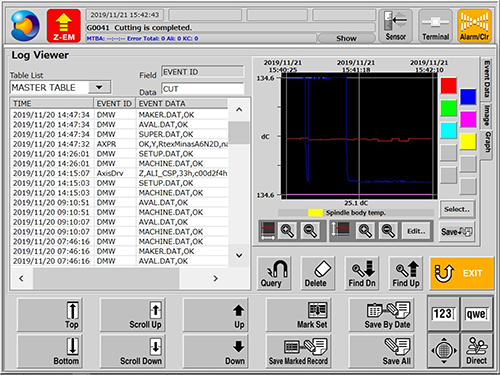

Graphic processing condition display similar to full automation equipment - Log viewer

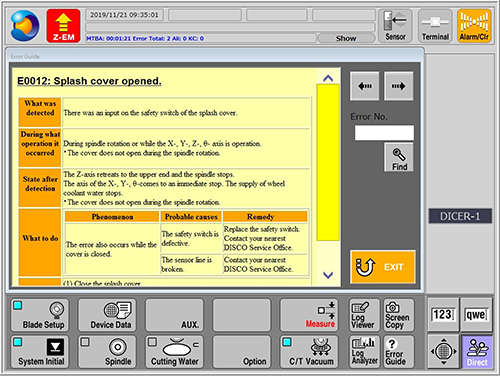

Graphic analog data display and equipment data visualization - Help viewer

Displays instructions when error occurs for quick, accurate recovery.

High maintainability

- Enhancement of Dust Prevention Performance on X-, Y-, and Z-axes.

Effective for materials including ceramics where contamination is likely to damage the shaft.

Specifications

| Specification | Unit | 1.8 kW | 2.2 kW (Option) | 2.2 kW (Option) (High torque) |

|

|---|---|---|---|---|---|

| Max. workpiece size | - | Φ8 inch (250 mm × 250 mm user-specified specification) | |||

| X axis | Cutting range | mm | 260 | ||

| Cutting speed | mm/s | 0.1 ~ 1,000 | |||

| Y-axis | Cutting range | mm | 260 | ||

| Index step | mm | 0.0001 | |||

| Index positioning accuracy | mm | 0.002/260 (Single error) 0.002/5 |

|||

| Z-axis | Max. stroke | mm | 31.2 | 31.4 | |

| Moving resolution | mm | 0.0000002 (0.2 nm) | |||

| Repeatability accuracy | mm | 0.001 | |||

| θ-axis | Max. rotating angle | deg | 320 Θ axis rotation specification 380°(option):382.5 |

||

| Spindle | Rated output | 1.8 at 60,000 min-1 | 2.2 at 30,000 min-1 | 2.2 at 15,000 min-1 | |

| Rated torque | N・m | 0.29 | 0.7 | 1.4 | |

| Rotation speed range | min‐1 | 6,000 ~ 60,000 | 3,000 ~ 30,000 | 3,000 ~ 15,000 | |

| Equipment dimensions(W×D×H) | mm | 880 × 1,000 × 1,800 | |||

| Equipment weight | kg | Approx. 1,100 | |||

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.