Standard dual spindle dicing saw

- Φ200 mm

- Facing dual spindle

- DBG

- Package Singulation

Maximized throughput

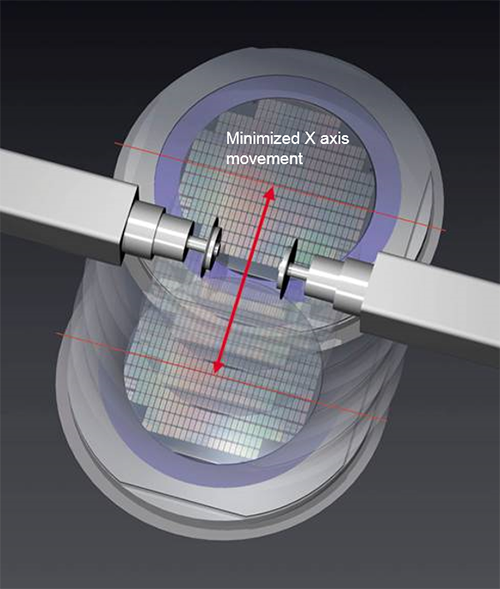

The DFD6340 features a facing dual-spindle configuration with a shorter distance between blades, which improves throughput by up to 30 % for step/bevel cut and 40 % for dual cut when compared with parallel dual spindle dicing saws.

Small footprint

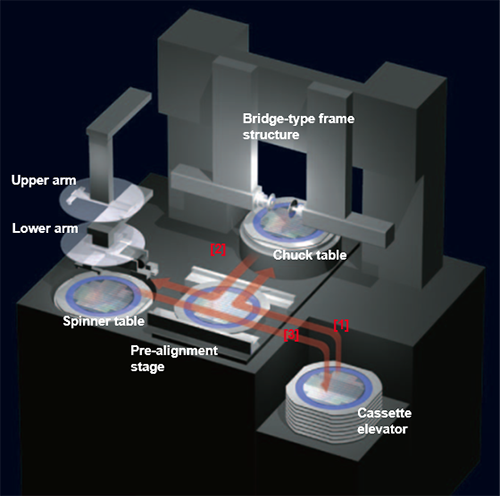

By employing a new high-rigidity, bridge-type frame structure, the DFD6340 has the smallest footprint of any 8" saw in its class.

Lower air and energy consumption

Utilizing the latest in conservation technology, the energy and air consumption of the DFD6340 has been reduced by 33 % and 24 % respectively when compared to the previous generation of saws.

Consistent cut quality

The DFD6340 offers consistent cut quality with the adoption of a Synchro Spindle™ featuring superior radial rigidity. An atomizing nozzle cleaning mechanism can also be included in the spinner unit as an option to effectively clean wafers after dicing (Patent no. 3410385).

Shorter set up time - two NCS* sensors

Two Non-Contact Setup sensors, one each for Z1 & Z2, enables increased throughput.

*optional function

Shorter kerf check time - two microscopes*

A dedicated high-magnification microscope for each spindle allows for simultaneous kerf checking for increased throughput.

*optional function

Process stability - cutting water flow control

Cutting water flow rate can be set in the device data. In addition, water flow rate is monitored during processing, making it possible to ensure a constant and stable flow rate.

Easy operation

The DFD6340 utilizes an adjustable LCD touch screen graphical user interface making operation and maintenance intuitive and easy. The inclusion of an inspection stage allows for the removal and checking of wafers after dicing during fully automatic operation.

DFD6340 Operation flow

-

Lower arm moves the workpiece from the cassette to the pre-alignment stage. Lower arm moves the workpiece to the chuck table → cutting →

-

Upper arm moves the workpiece to the spinner table → cleaning & drying →

- Lower arm returns the workpiece to the cassette

Specifications

| Specification | Unit | 1.2, 1.8 kW | 2.2 kW | |

|---|---|---|---|---|

| Max. workpiece size | - | Φ8 inch | ||

| X-axis | Cutting range | mm | 210 | |

| Cutting speed | mm/s | 0.1 ~ 600 | ||

| Y1・Y2-axis | Cutting range | mm | 210 | |

| Index step | mm | 0.0001 | ||

| Positioning accuracy | mm | Within 0.002/210 (Single error) Within 0.002/5 |

||

| Z-axis | Max. stroke | mm | 19.22 (For Φ2 inch blade) | 19.9 (For Φ3 inch blade) |

| Moving resolution | mm | 0.00005 | ||

| Repeatability accuracy | mm | 0.001 | ||

| θ-axis | Max. rotating angle | deg | 380 | |

| Spindle | Rated torque | N・m | 0.19(1.2 kW) 0.29(1.8 kW) |

0.7 |

| Rotation speed range | min‐1 | 6,000 ~ 60,000 | 3,000 ~ 30,000 | |

| Equipment dimensions(W×D×H) | mm | 1,180 × 1,110 × 1,850 | ||

| Equipment weight | kg | Approx. 1,600 | ||

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.