PRODUCT SERIES - XR SERIES

The XR-Series is a range of 19” rack mountable water-to-water heat exchangers, designed for use with primary water circuits, providing cooling to applications for which the facilities water may be unsuitable.

Due to the 19” rack mountable design, the XR-Series is ideal for utilising wasted space, allowing cooling systems to be mounted within electrical racking, as other components become smaller, and systems are modernised.

How do rack-mounted water-to-water heat exchangers work?

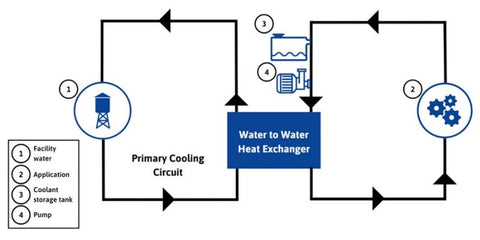

As demonstrated in the diagram on the previous page, water-to-water heat exchangers are able to address facility water concerns, overcoming issues associated with insufficient pressure, fluctuating flow, or very cold water, by providing a stable supply of coolant to the process, regardless of the facility water condition, ensuring that processes remain at optimum performance. Sitting between the application and the primary water circuit, the water-to water heat exchanger is able to modulate the flow rate of facility water to achieve temperature stability, without the need for a refrigeration circuit. It is also able to provide a layer of protection against microbial contamination for more sensitive equipment. Plate heat exchangers are utilised in the design of the XR-Series by Applied Thermal Control, allowing for efficient heat transfer to occur in a small space.

What are the benefits of a rack mounted water-to-water heat exchanger?

Ideal for a reduced system footprint

Rack mounted water-to-water heat exchangers can be mounted within existing racking. This allows space to be utilised effectively following refurbishment and modernisation of systems.

Easy to install

The compact size of rack mounted water to water heat exchangers also makes them easier to install and integrate into existing systems.

Plate heat exchangers are quick and easy to clean

Periodic, onsite cleaning will flush out any contaminants, preventing fouling and eventual reduction in heat transfer.

Adjusting the cooling capacity of a plate heat exchanger is simple.

If the requirements of the application increase or decrease, it may be possible to exchange the plate heat exchanger for one with more or fewer plates. A reduction in the number of plates will result in a reduction in cooling capacity.

Heat exchangers are responsive.

Because fluids are flowing through a narrow channel, only a small volume of fluid is contained by the plate heat exchanger at any one time. This makes it possible to control temperatures with minimal lag times.

Plate heat exchangers are efficient

The structure of the plate heat exchangers make it possible to recover up to 90% of the heat from process fluids.

Heat exchangers operate quietly.

Because unwanted heat is transferred into the primary cooling circuit, fans are not required in the design of a water-to-water heat exchanger. A fan ejecting unwanted heat is usually the noisiest part of process cooling equipment.

Upgrades to air conditioning/ventilation are unnecessary.

Unwanted heat is contained within the primary cooling circuit, rather than being ejected into the surrounding air by fans. This means that upgrades to air conditioning or ventilations within the building are not needed, resulting in lower energy costs and a reduced carbon footprint.

Heat Transfer Fluids

In scenarios where water alone is insufficient as a heat transfer fluid, due to its low boiling point, freezing point, or corrosiveness, glycol-based fluids may be used. Ethylene Glycol (Hexid) and Propylene Glycol (CoolFlow) mixtures have lower freezing points than water and are also non-corrosive and can help to prevent the build-up of scale and other deposits, such as microbial contamination, when a biocide is present. When selecting a heat transfer fluid, it is important to consider factors such as temperature range, viscosity, and chemical compatibility with the materials used in the heat exchanger. It is also important to follow the manufacturer's recommendations for the use and handling of the heat transfer fluid.

The XR-Series from Applied Thermal Control

The XR-Series is a self-contained system, comprised of a modulated primary supply, the water-to-water heat exchanger, and the coolant storage tank. A wide range of non-ferrous/stainless steel pumps are available, both positive displacement and centrifugal, with varying flows and pressures to suit a multitude of requirements. All pumps have fan-cooled electric motors and are supplied in 304 & 316 stainless steel as standard.

The XR-Series is suitable for use with a wide range of fluids including:

- Water

- Glycols

- Oils

Features of the XR-Series:

- Supplied complete with circuit breakers and on/off switches.

- Coolant pump starting contactors

- Pump motor protection

- IP54 protection

- 24V control circuit available

- Temperature gauge

- Pressure gauge

- Coolant safety bypass

- Visual tank level indicator

The XR-Series

XR04

The XR04 helps you to utilise otherwise wasted space within 19” electrical rack enclosures. It is designed to provide 4kW of cooling at 10°C above the temperature of the primary water circuit.

Commonly requested options:

Commonly requested options:

- High temperature pack, available to +75ºC

- Non-return solenoid valves

- In-line deionising cartridge and fittings

- Castors to replace rubber feet

- CPC quick release connectors

- Installation kit

- Particulate filter

- Fan speed control (on/off)

XR08

The XR08 allows space within existing 19” electrical rack enclosures to be utilised, reducing system footprint. It is able to provide 8kW of cooling at 10°C above the temperature of the primary water circuit.

Commonly requested options:

- High temperature pack, available to +75ºC

- Non-return solenoid valves

- In-line deionising cartridge and fittings

- Castors to replace rubber feet

- CPC quick release connectors

- Installation kit

- Particulate filter

- Fan speed control (on/off)

XR15

The XR15 is designed to be mounted within 19” electrical racking, minimising system footprints and utilising otherwise wasted space. It provides 15kW of cooling at 10°C above the temperature of the primary water circuit.

Commonly requested options:

- High temperature pack, available to +75ºC

- Non-return solenoid valves

- In-line deionising cartridge and fittings

- Castors to replace rubber feet

- CPC quick release connectors

- Installation kit

- Particulate filter

- Fan speed control (on/off)

- Onboard RS485 data protocol

Common Applications include:

- Laser systems

- X-ray sources

- Resistance welding machines

- High frequency generators

- Furnaces

- General process cooling