Grinder for thinning difficult-to-process materials

- Φ150 mm

- 4 axes, 5 chuck tables

Support for the grinding of hard and brittle materials

This equipment is suitable for grinding difficult-to-process materials such as sapphire and SiC. DFG8830 is equipped with high power, high rigidity spindles and is compatible with large-diameter grinding wheels, making it possible to achieve fully automatic processing for difficult-to-process materials.

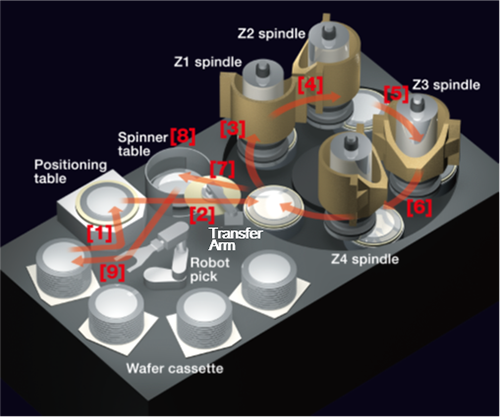

4-axis, 5-chuck table configuration

The 4-axis, 5-chuck table, and 1 turntable configuration offers solutions for a variety of applications. By selecting the optimal wheel for each of the 4 axes, this unit offers for low-damage, high-quality or high-productivity processing for a wide range of applications.

Grinding of wafers with supporting substrates

DFG8830 is compatible with workpieces bonded to substrates such as glass or ceramic. This equipment supports substrate sizes from Φ5 to 8-inch and workpieces with substrates up to a total thickness of 3.5 mm.

Small footprint

Optimal arrangement of the spindles and handling systems has resulted in a compact footprint of 3.5 m2, despite boasting an all-in-one, 4-axis, 5-chuck table configuration.

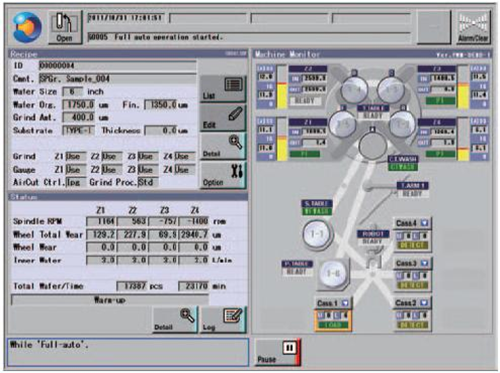

User friendly operation

The intuitive icon-based GUI touch panel allows simple operation and on-screen step-by-step visualization of the processing stages. Also, with support for up to four cassettes, the cassette replacement frequency and equipment operation workload can be reduced.

Work Flow System

- The robot pick removes the wafer from the cassette and places it on the positioning table, where centering takes place.

- The transfer arm places the wafer on the chuck table.

- Z1-axis grinding

- Z2-axis grinding

- Z3-axis grinding

- Z4-axis grinding

- The transfer arm removes the wafer from the chuck table and places it on the spinner table.

- Cleaning and drying

- The robot pick returns the workpiece to the cassette.

Specifications

| Specification | Unit | ||

|---|---|---|---|

| Supported workpiece size | - | Φ4, 5, 6 inch | |

| Substrate Diameter | - | Φ5, 6, 8 inch | |

| Grinding method | - | In-feed grinding with wafer rotation | |

| Grinding wheel | - | Φ300 mm Diamond Wheel | |

| Spindle | Rated output | kW | 6.3 |

| Rotation speed range | min‐1 | 1,000 ~ 4,000 | |

| Equipment dimensions (W x D x H) | mm | 1,400 × 2,500 × 2,000 | |

| Equipment weight | kg | Approx.6,000 | |

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.