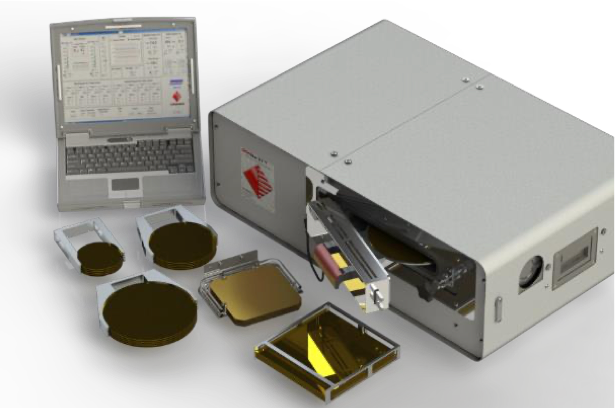

Robust measurement system and full range combination measurement system

VIM-1 Spinning rotor gauge instrument

- Measurement range 1×10-6 to 10 mbar (7.5×10-7 to 7.5 Torr)

- Easy to use by one-button operation

- Corrosion resistant 316 stainless steel sensor

- Low-cost disposable sensor for industrial applications

- Full-range package with SmartPirani™ transducer available

ADVANTAGES

- Excellent long-term stability

- Digital RS-232 or RS-485 interface

- Bakeable all-metal sensor design

- Passive high vacuum sensor without ion- or heat source

The VIM-1 instrument is based on a robust spinning rotor gauge vacuum sensor that measures the pressure-dependent molecular drag on a magnetically levitated spinning steel ball.

APPLICATION

- Cryogenic and liquid gas vessels

- Vacuum insulation panel (VIP)

- Rate-of-rise outgassing testing

Download brochure here

VIM-1 SPINNING ROTOR GAUGE SPECIFICATIONS

Specifications |

|

|

Measuring range

|

1×10-6 to 10 mbar (7.5×10-7 to 7.5 Torr)

|

|

Measuring principle

|

Molecular drag from rotating steel ball

|

|

Accuracy 1×10-6 to 9.99×10-5 mbar

|

10% of reading

|

|

Accuracy 1×10-5 to 1 mbar

|

3% of reading

|

|

Measurement update rate (user selectable)

|

3, 5, 10 and 20 seconds

|

|

Measurement readout

|

6 digits LED

|

|

Interfaces

|

USB 2.0, RS-485, RS-232 printer port

|

|

Relays

|

2 SPDT, 48 VDC 0.5A

|

|

Data logging storage

|

1,023 values

|

Environment conditions |

|

|

Operating ambient temperature

|

+10 to +40 °C (50 to +104 °F)

|

|

Protection rating, EN 60529/A2:2013

|

IP40

|

|

Humidity, IEC 68-2-38

|

98%, non-condensing

|

|

Power supply

|

|

|

Supply voltage

|

100 - 242 VAC, 50-60 Hz

|

|

Power consumption

|

<50W

|

Materials |

|

|

Vacuum exposed materials (media wetted)

|

SS 1.4404 / AISI 316 stainless steel

|

| Enclosure | SS 1.4404 / AISI 316 stainless steel |

| Protection rating, EN 60529/A2:2013 | IP68 |

| Process leak tightness | <1·10-9 mbar·l/s |

You may also like

More from SENS4

More from Newest Products

Recently viewed