The PECVD process modules are specifically designed to produce excellent uniformity and high rate films, with control of film properties such as refractive index, stress, electrical characteristics and wet chemical etch rate.

-

High quality films, high throughput, excellent uniformity

- Wide temperature range electrode

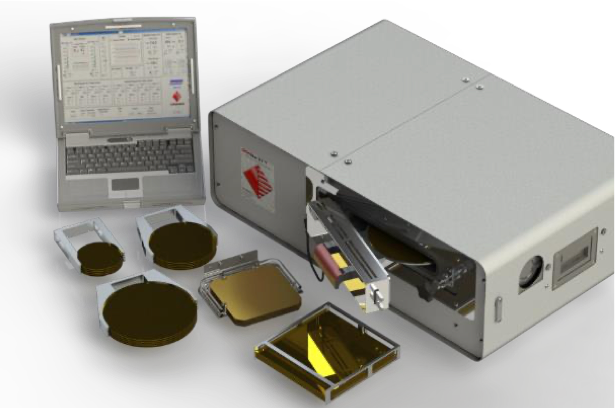

- Compatible with all wafer sizes up to 200mm

- Rapid change between wafer sizes

- Low cost of ownership and ease of serviceability

- Resistive heated electrodes with capability up to 400°C or 1200°C

- In-situ chamber cleaning and end-pointing

System Features:

Delivers reactive species to the substrate, with a uniform high conductance path through the chamber

Allows a high gas flow to be used while maintaining low pressure

Variable height electrode

Utilises the 3D characteristics of the plasma and accommodate substrates up to 10mm thick at optimum height

Wide temperature range electrode (-150°C to +400°C)

Can be cooled by liquid nitrogen, a fluid re-circulating chiller or resistively heated

A fluid controlled electrode fed by a re-circulating chiller unit Excellent substrate temperature control

RF powered showerhead with optimised gas delivery

Provides uniform plasma processing with LF/RF switching allowing precise control of film stress

ICP source sizes of 65mm, 180mm, 300mm

Delivers process uniformity up to 200mm wafers

High pumping capacity

Gives wide process pressure window

Wafer clamping with He backside cooling

Optimum wafer temperature control

Upgrades/Accessories:

Dry pump N2 standby mode - Saves energy and nitrogen

Gas pod - incorporate extra gas lines and allow greater flexibility

Logviewer software - datalogging software allows realtime graphing and post run analysis

Optical end point detectors - an important tool for achieving optimal process results

Soft pump - allows the slow pumping down of a vacuum chamber

Turbomolecular vacuum pump - offers superior pumping speeds and higher throughput

X20 Control System - delivers a future proof, flexible and reliable tool with increased system ‘intellect’

Advanced Energy Paramount generator - Offering increased reliability and greater plasma stability

Automatic pressure control - This controller ensures very fast and accurate pressure control

Dual CM gauge switching - provides the ability to utilise two differing ranges of capacitance manometer via a single pressure control valve

LN2 autochangeover unit - enables table cooling fluid to be automatically switched between Liquid Nitrogen (LN2) and Chiller Fluid

TEOS liquid level sensing - level sensing is achieved using ultra sonic level sensors fitted to the TEOS canister

Wide temperature range electrode - significant design improvements to increase process performance

Applications:

- High quality PECVD of silicon nitride and silicon dioxide for photonics, dielectric layers, passivation and many other uses

- Hard mask deposition and etch for high brightness LED production