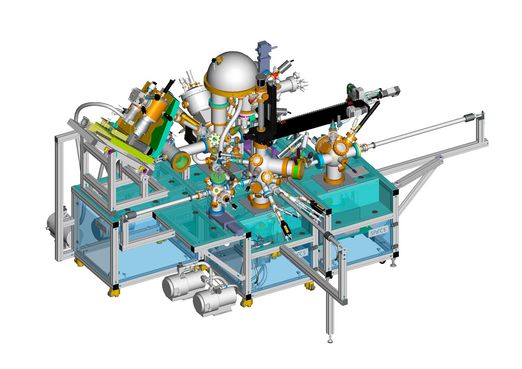

Laboratory ARPES system with PHOIBOS Analyzers with 3D Spin Detection System and small spot X-ray und UV sources.

KEY FEATURES

- PHOIBOS ARPES Analyzer with 3D Spin Detector

- Energy Resolution <1.8 meV

- Angular Resolution <0.1°

- Monochromated Small Spot UV and X-Ray Source with High Intensity

- Low Temperature 5 Axes Manipulator

- Sample Strorage and Transfer Chamber

- Pressure in Analysis Chamber <2 x 10-10 mbar

- Sample Preparation Module

- Open and Modular System Design

- Designed and Tested in Berlin, Germany

The SPECS system for laboratory Spin-ARPES is a fully equipped UHV analysis system for modern surface analysis including ARPES, Spin-ARPES and XPS. All systems are designed and manufactured at the SPECS headquarter in Berlin. A special engineering group personally accompanies the system process from the order placing until the final acceptance. Our engineers are dedicated to highest quality and usability of the system during design, testing and setup on site. Once the system is in full operation a professional service team in our HQ and our worldwide branch offices takes care of a smooth and stable operation.

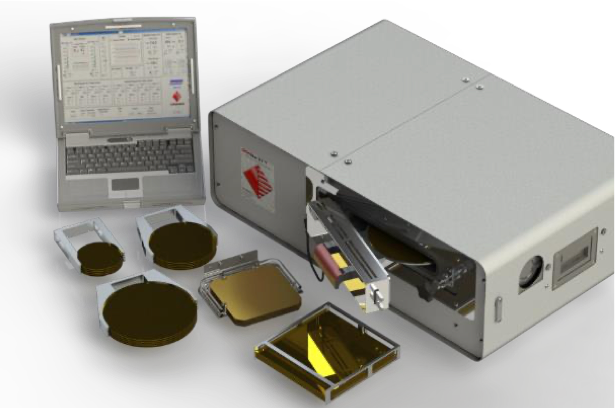

The SPECS lab ARPES system comes with the PHOIBOS analyzer series with 3D Spin Detectors in combination with a ultra low temperature manipulator, sophisticated sample handling and a monochromated small spot UV- and X-ray source. The analysis module is based on a special µ-metal chamber optimized for low kinetic energy analysis. A dedicated surface science preparation module with all necessary techniques (surface cleaning, LEED, deposition, sample storage) is included as well as a fast entry loadlock.

The typical vacuum achieved in SPECS systems is better than 2 x 10-10 mbar achieved during assembly at SPECS. A final end pressure in the 10-11 mbar range is achievable. The standard pumping configuration consist of and ion getter pump (IGP), a titan sublimation pump (TSP) and a turbo molecular pump (TMP) with connecting to a roughing vacuum. Different pumping configurations are available on request including cryo pumps, larger pumping schemes and also NEG pumps.

All Systems are equipped with a rigid frame and included bake-out tents with automated heating systems. An electronics cabinet hosts all relevant electronics, a main power supply and a TCP/IP based communication platform for the control units.

All SPECS systems are ready for interconnections to other SPECS modules. Also, the connection to existing systems can be tested on request.