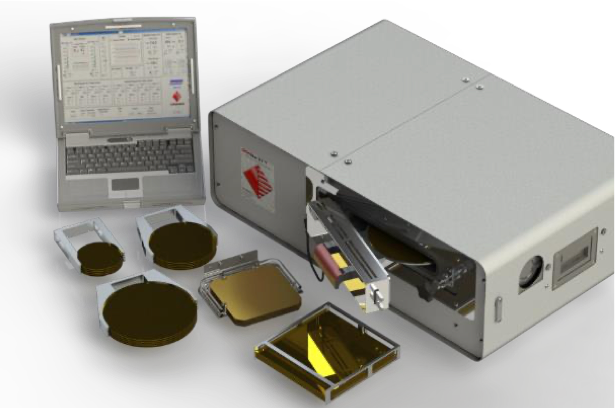

The inertDEP Physical Vapour Deposition (PVD) system is a cost-effective, compact, high-vacuum evaporator for metal and/or organic materials that are moisture and/or oxygen sensitive. The inertDEP system can be integrated within an inert nitrogen or argon atmosphere with a glovebox environment.

All internal system components are easily removable for material replenishment or cleaning within a glovebox.

The system comes as standard with one-touch automatic pump down and vent routines. The deposition control can either be manual or fully automatic to suit your budget.

All materials have been carefully selected and engineered for high vacuum compatibility and minimal outgassing for quick pump down times to high vacuum pressure regimes.

A large 15" touch screen HMI allows for easy intuitive control of the vacuum and deposition control operation.

All inertDEP systems are engineered and assembled within our Sydney headquarters and backed by market leading 2 year warranty.

Typical applications include Quantum computing, wearable electronics, photovoltaics, perovskite solar cells, OLEDs, OPVs, and OFETS. Organic active layers in perovskite solar cells, OLEDs, OPVs, and OFETS.

Specifications

Substrate Size & Uniformity

4" Diameter max or smaller pieces

+/- 5% uniformity across 4" Diameter substrate

Base Pressure

<5x10E-7 mbar/Torr

Source Configuration

4x Metal only

4x 1cc Organic only

2x Metal plus 2x Organic

3x 2" Magnetron Sputter Sources

Magnetron Sputtering + Thermal + Organic available

Max Source Temperatures

Metal = 1800C

Organic = 600C

Co-Deposition Available

Yes - Max either two Metals or two Organic sources

Vacuum Pumping System

Turbo molecular pump (field serviceable) backed by oil free dry scroll pump

Interlocks

Vacuum and water flow

Glovebox Integration

Available with or without glovebox.

Warranty

2 Years

Country of Manufacture

Australia