Introduction

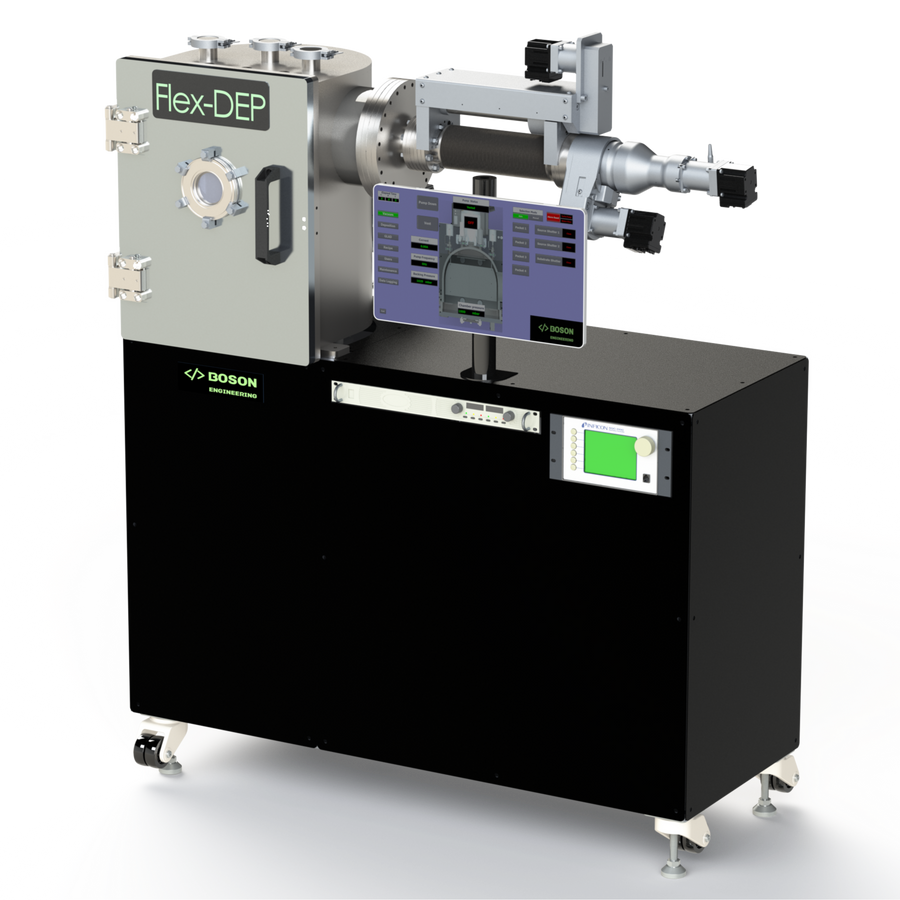

The flexDEP Physical Vapour Deposition (PVD) system is a modular, flexible, high-vacuum evaporator for metal, dielectrics and/or organic materials.

The system comes as standard with a Siemens PLC industrial controller for reliable software automation. The deposition control is fully automatic with PID loop control for precise thin film thickness determination.

All materials have been carefully selected and engineered for high vacuum compatibility and minimal outgassing for quick pump down times to high vacuum pressure regimes.

A large 22" touch screen HMI allows for easy intuitive control of the vacuum and deposition control operation.

All flexDEP systems are engineered and assembled within our Sydney headquarters and backed by market leading 2 year warranty.

Typical applications include quantum computing, wearable electronics, photovoltaics, MEMs, bio-medical, perovskite solar cells, OLEDs, OPVs, and OFETS. Organic active layers in perovskite solar cells, OLEDs, OPVs, and OFETS.

Specifications

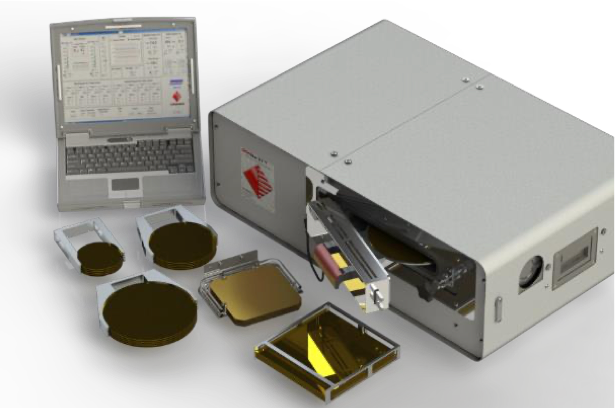

Substrate Size & Uniformity

6" Diameter max or smaller pieces

+/- 5% uniformity across 6" Diameter substrate

Base Pressure

<5x10E-7 mbar/Torr (Turbo Pump)

<5x10E-8 mbar/Torr (Cryo Pump)

Deposition Source Types

Resistive Thermal Evaporation

Magnetron Sputtering

E-Beam Evaporation (single or multi-pocket)

Low-Temperature Organic Evaporation

Substrate Temperature Options

Heating = up to +300C / +500C / +800C

Cooling = down to room temperature / -10C / -150C

Various other heating/cooling ranges available on request

Options Available

Load Lock (single load or cassette)

Ion Assisted Deposition/Etching

RF/DC substrate bias

Residual Gas Analyser

Cooled vacuum chamber

Chamber bakeout

Glancing Angle Deposition Stage (substrate tilt & rotation)

Standards

AS3000 Australian wiring and safety standards

Control System

Siemens S7 PLC with safety relays

Warranty

2 Years

Country of Manufacture

Australia