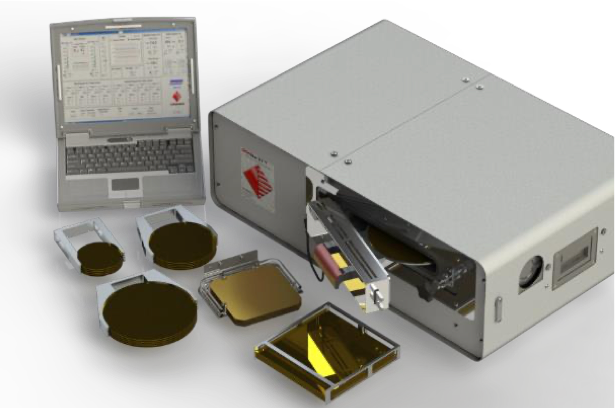

COOLVAC 1500 iSL

Cryogenic Pump with electronics

The iSmartLine (iSL) operates automatically and is equipped with pressure gauge, fore-vacuum valve and electrical heaters.

It has several variants of high vacuum flanges (DN 200 ISO-K, DN 200 CF or 6" ANSI) and is supplied with a DN 25 KF backing flange and a DN 40 KF safety valve at flange. Further flanges are in size DN 16 KF.

The pumping speed for molecular nitrogen (N2) is 1,500 l/s, for hydrogen (H2O) 4,600 l/s; the capacity for molecular nitrogen (N2) 15 bar*l, for molecular hydrogen (H2) 15 bar*l.

For variants with different, optional flange sizes or customized properties please do not hesitate to contact your local sales team or application management team.

COOLVAC i - Cryogenic pumps

Fulfilling the rapidly increasing requirements for cryogenic pump systems.

Guaranteed high quality, high reliability and impressive performance data

The new COOLVAC i serie, with its new smart family of cryogenic pumps is perfectly adapted to both current and future economic trends and cycles.

We have combined the new compact COOL.DRIVE i controller which is easy to operate with the high performance, low vibration and energy efficient cold heads and compressors of the respective i series.

Highly effective pumping speed for all gases, water vapor in particular

Automatic control via COOL.DRIVE i controller

Boost, Eco or standard operation mode for fast cool down, energy saving or standard operation via communication with compressor (for pumps > 5000 l/s)

Integrated safety valve according EN 4126

Simple and rapid maintenance

Depending on the variant, the cryogenic pumps offer different features:

iBL Basic line pumps without automatic control

iSL Smart line with automatic control and boost/eco mode

iLN2 liquid nitrogen cooled shield

COOLVAC 1500 iSL

Specifically developed for coating, Semiconductor adjacent and R&D market applications, this new generation of cryogenic pumps offers high reliability, low cost of ownership and small footprint. Depending on your needs you can easily operate the pump either in vertical or in horizontal position. No matter which orientation, their maintenance is simple.