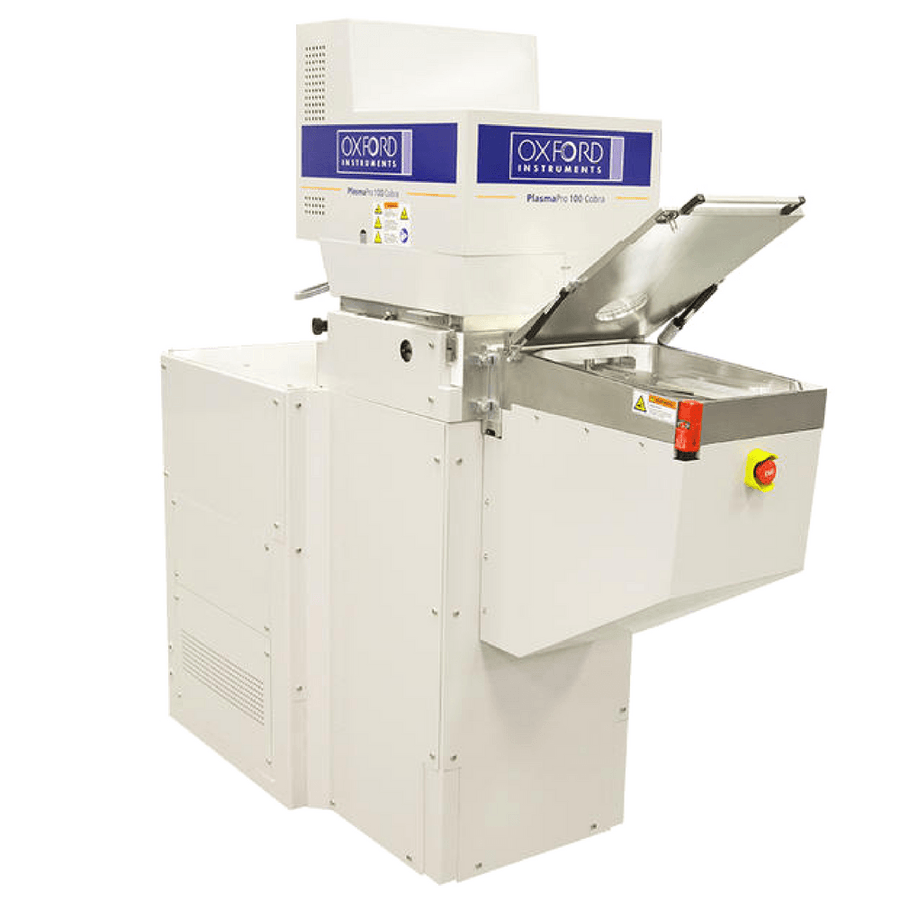

The PlasmaPro 100 RIE modules deliver anisotropic dry etching for an extensive range of processes.

- Compatible with all wafer sizes up to 200mm

- Rapid change between wafer sizes

- Low cost of ownership and ease of serviceability

-

Excellent uniformity, high throughput and high precision processes

- In-situ chamber cleaning and end-pointing

-

Wide temperature range electrode, -150°C to 400°C

System Features:

-

Delivers reactive species to the substrate, with a uniform high conductance path through the chamber

Allows a high gas flow to be used while maintaining low pressure -

Wide temperature range electrode (-150°C to +400°C)

which can be cooled by liquid nitrogen, a fluid re-circulating chiller or resistively heated - An optional blow out and fluid exchange unit can automate the process of switching modes -

A fluid controlled electrode fed by a re-circulating chiller unit

Excellent substrate temperature control - High pumping capacity - gives wide process pressure window

-

Wafer clamping with He backside cooling

Optimum wafer temperature control

Applications:

- III-V etch processes

- Solid State Lasers InP etch

- VCSEL GaAs/AlGaAs etch

- RF device low damage GaN etch

- Diamond Like Carbon (DLC)deposition

- SiO2 and quartz etch

- Failure analysis dry etch de-processing ranging from packaged chip and die etch through to full 200mm wafer etch

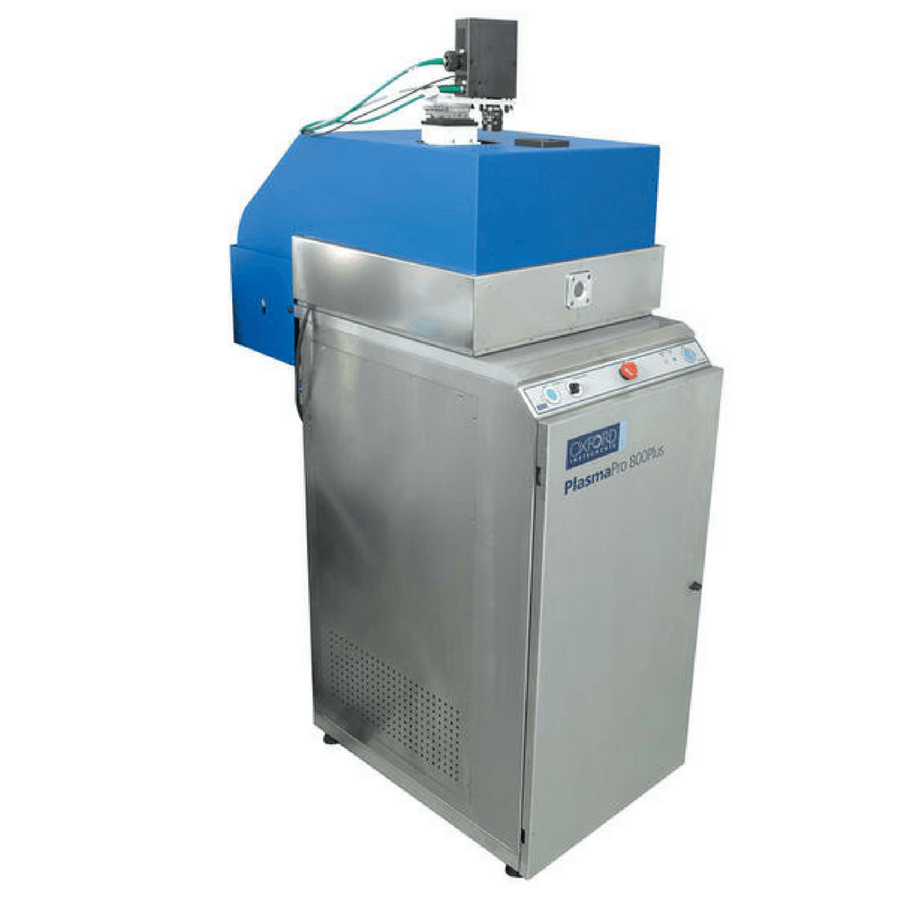

You may also like

More from Oxford Instruments Plasma

More from Dry Plasma Etching

Recently viewed