PVD systems - Benchtop

3 products

3 products

High-performance, high-vacuum deposition systems in compact packages for benchtop location. Superior, efficient performance for a multitude of R&D thin-film deposition applications.

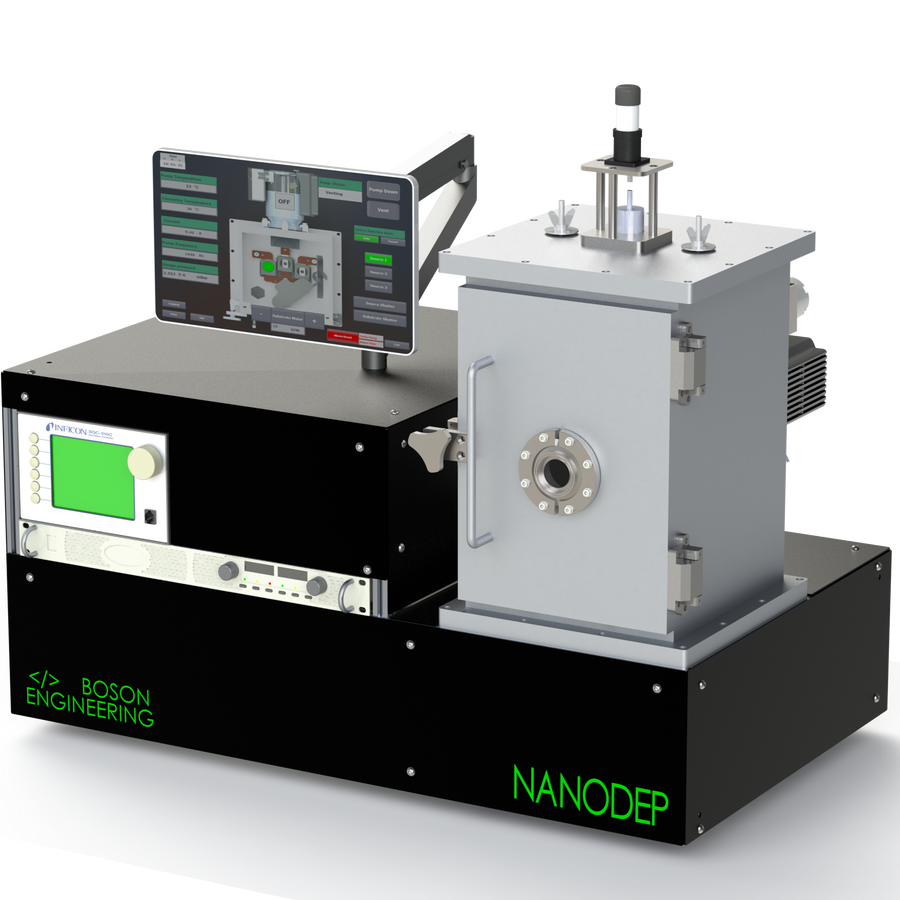

The nanoDEP Physical Vapour Deposition (PVD) system is a cost-effective, compact, high-vacuum evaporator for metal and/or organic materials.

The system comes as standard with one-touch automatic pump down and vent routines. The deposition control can either be manual or fully automatic to suit your budget.

All materials have been carefully selected and engineered for high vacuum compatibility and minimal outgassing for quick pump down times to high vacuum pressure regimes.

A large 15" touch screen HMI allows for easy intuitive control of the vacuum and deposition control operation.

All nanoDEP systems are engineered and assembled within our Sydney headquarters and backed by market leading 2 year warranty.

Typical applications include metal electrical contacts for Quantum computing, wearable electronics, photovoltaics, perovskite solar cells, OLEDs, OPVs, and OFETS. Organic active layers in perovskite solar cells, OLEDs, OPVs, and OFETS.

Subscribe today to hear first about our new and exciting technology