Atomic Layer Deposition Systems

3 products

3 products

The inherent strength of ALD technology is the ability to utilize much of the materials available on the periodic table as shown below. In addition, conformality and the ability to adapt to various substrates, shapes and high aspect ratio structures producing uniform, pinhole free single material and nano-laminate coatings has created broad interest in many fields.

Arradiance process and equipment technologies were forged in the most challenging ALD Nanofilm environment: electrically functional nanofilms on substrates possessing both high surface areas (>9m2) and high aspect ratios (>>100:1).

Nano Vacuum offers both Arradiance (USA) and Oxford Instruments (UK) ALD Systems.

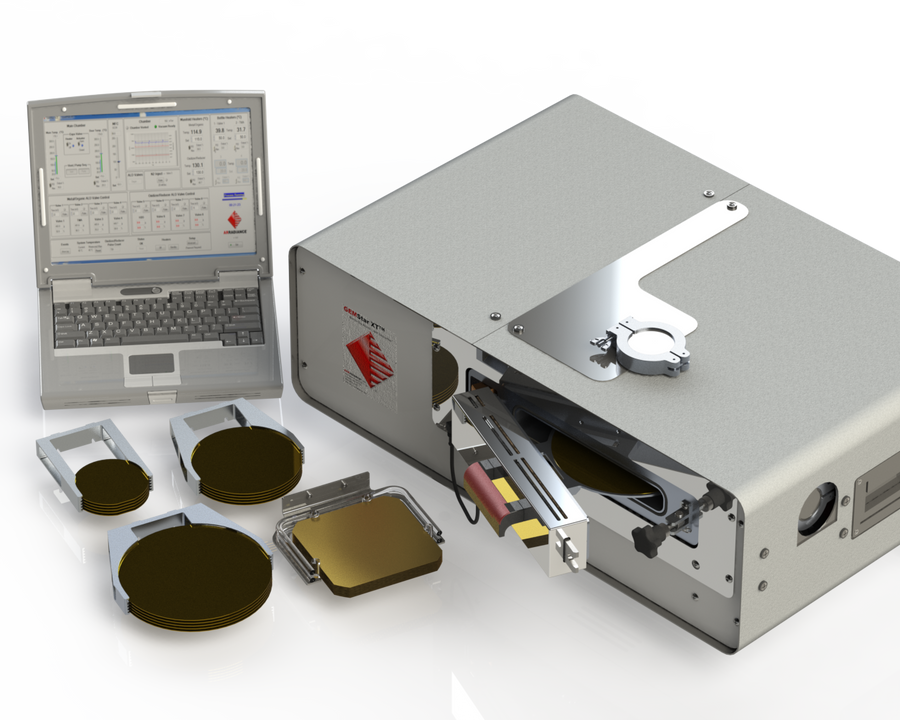

The Arradiance (USA) GEMStar XT product family delivers high quality performance in a compact Benchtop platform. Now with more configurable options to meet specific Customer requirements and budgets, we are confident that GEMStar can take your ALD research or low volume manufacturing to the next level.

XT systems can be configured as single (4 ALD port) or dual (8 ALD port) 200 °C manifolds with four easily locatable ALD bottle material heated zones, and up to four external gas lines. All systems have one port equipped with our Pulsed Vapor Push technology for low vapor pressure materials.

The GEMFlow™ scripting software allows easy creation of jobs for the most complicated nanolaminate films providing real time history of process and equipment parameters.

Oxford Instruments’ ALD product family offers a unique range of flexibility and capability in the engineering of nanoscale structures and devices by combining remote plasma ALD processes with thermal ALD.

The FlexAL systems provide a new range of flexibility and capability in the engineering of nanoscale structures and devices by offering remote plasma atomic layer deposition (ALD) processes and thermal ALD within a single ALD system.

Subscribe today to hear first about our new and exciting technology